Emptying the Fuel Tank

Important

because the engine may be damaged.

Do not overfill the crankcase with oil

1.

Stop the engine and wait for it to cool.

8.

Replace and tighten the dipstick.

Important

Drain gasoline from a cold engine only.

Lubricating the Machine

2.

3.

4.

Disconnect the wire from the spark plug.

Remove the cap from the fuel tank.

Oiling the Caster Wheels and Pivot

Points

Use a pump-type syphon to drain the gasoline into a

clean approved gasoline container.

Lubricate the caster wheels and pivot points yearly.

5.

6.

Connect the wire onto the spark plug.

Run the engine until it stops.

1.

2.

Stop the engine and pull the wire off of the spark plug.

Place a few drops of engine oil in the following

locations:

7. Start the engine again to make sure that all the

gasoline is out of the carburetor.

•

•

Each of the caster wheel bushings

Where the front wheel support pivots in the engine

base (Fig. 22)

Servicing the Spark Plug

Check the spark plug after every 100 operating hours or

yearly whichever comes first. Ensure that the air gap

between the center and side electrodes is correct before

installing the spark plug. Use a spark plug wrench for

removing and installing the spark plug and a gapping

tool/feeler gauge to check and adjust the air gap. Install a

new spark plug if necessary.

•

Where the rear traction shafts pivot in the engine

base (Fig. 22)

2

2

Type: Champion RCJ–8 or equivalent.

Air Gap: 0.030 in. (0.76 mm)

3

2

2

Removing the Spark Plug

1.

2.

3.

4.

Stop the engine.

Pull the wire off of the spark plug (Fig. 18).

Clean the area around the spark plug.

Remove the plug from the cylinder head.

1

4

1826

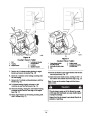

Figure 22

1.

2.

Rear idler assembly

Oil point

3.

4.

Grease point

Checking the Spark Plug

Traction shafts

1.

Look at the center of both spark plugs (Fig. 23). If you

see light brown or gray on the insulator, the engine is

operating properly. A black coating on the insulator

usually means the air cleaner is dirty.

Greasing the Rear Idler Assembly

Lubricate the rear idler assembly with No. 2 general

Important

the spark plug when it has a black coating, worn

electrodes, an oily film, or cracks.

Never clean the spark plug. Always replace

purpose grease after every 25 hours of operation or more

frequently when conditions are dusty or sandy (Fig. 22).

Pump grease into the fitting until it oozes out of the

bearings.

2.

Check the gap between the center and side electrodes

(Fig. 23).

16

| Categories | Blower Vacuum and Sweeper Manuals, Toro Blower and Vacuum Manuals |

|---|---|

| Tags | Toro 62925 |

| Model Number | 62925 |

| Model Year | 2002 |

| Download File |

|

| Document Type | Operator's Manual |

| Language | English |

| Serial Number | 220000001 - 220999999 |

| Product Name | 5.5 hp Lawn Vacuum |

| Product Brand | Toro. Customer Service Representatives are available by phone:

Monday - Friday 7:30 a.m. to 9:00 p.m. (CDT) - Saturday 8:00 a.m. to 8:00 p.m. (CDT) - Sunday 10:00 a.m. to 8:00 p.m. (CDT)

Canada 1-888-225-4886 USA 1-888-384-9939, Blowers, Vacuums |

| Product Type | Blower, Vacuum |

| Product Series | Gas Powered, Lawn Vacuum / Sweeper / Blower |

| Swath | 30 inch |

| Discharge | 1000 cfm/28 cu.m/min |

| Engine Manufacturer | Briggs & Stratton |

| Engine Motor Model # | 126402-0245-E1 |

| Engine Motor Size | 5.5 hp |

| Engine Motor Type | 4 Cycle EPA1 |

| Transmission Speed | 1 Speed |

| Transmission Type | Capstan |

| Document File Type | |

| Publisher | toro.com |

| Wikipedia's Page | Toro Company |

| Copyright | Attribution Non-commercial |

(0 votes, average: 0 out of 5)