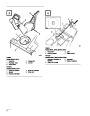

IMPORTANT: Belt must be on top of roller as

shown.

proper performance and prevent damage to underside

of snowthrower. Always replace both blades at the

same time.

5.

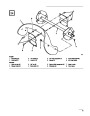

Reinstall belt cover. Tighten fasteners securely,

but DO NOT OVERTIGHTEN.

Note:

Whenever rotor blades are replaced,

scraper should also be replaced to

ensure proper snowthrower operation

and performance.

Replacing Spark Plug

Note:

Rotor blades wear rates are determined

by the running time and the roughness

of the driveway or sidewalk.

Before each snow season, check the spark plug. If

electrodes in center of plug are dark or have

deteriorated, install a new plug. Use an NGK

BPMR4A spark plug and set gap at .032” (.81 mm).

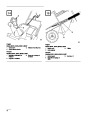

Removing Old Blade

1.

Remove (4) torx screws and (4) lock nuts

securing outer edges of rotor blade to rotor shaft

assembly (Fig. 24).

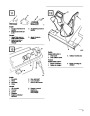

1.

2.

REMOVE CONTROL PANEL

(Fig. 20)—Remove (3) capscrews securing

control panel to housing. Remove ignition key

and lift off panel, allowing it to hang on recoil

rope.

2.

Next, remove (2) hex–head capscrews, spacers

and lock nuts securing center of blade to rotor

halves (Fig. 24).

REMOVE SPARK PLUG (Fig. 21)—Pull wire

off spark plug and remove plug. Examine the

plug and replace if cracked, fouled or dirty. DO

NOT SANDBLAST, SCRAPE OR CLEAN

SPARK PLUG BECAUSE DIRT MAY

RELEASE AND FALL INTO CYLINDER

CAUSING ENGINE DAMAGE.

3.

4.

Loosen the hex–head screw securing the rotor

halves to the auger shaft assembly (Fig. 24).

Slide the blade out from between the rotor halves

(Fig. 24).

Installing New Blade

3.

INSTALL SPARK PLUG—Set air gap (Fig. 22)

1.

The rotor blades are made of laminated rubber.

Examine the edge of a blade to see the difference

in layer thicknesses (Fig. 25). (Some blades have

a part number on the thick side of the blade.)

between electrodes at .032” (.81 mm).

Install

plug and tighten to 15 ft–lb (20.4 N m). If torque

wrench is not used, tighten plug firmly. Push

wire onto spark plug and reinstall control panel

with (3) capscrews.

Both blades must be installed with the thick

layer on the inside of the curve. If one blade is

installed with the thick layer on the outside of

the curve and the other blade installed with the

thick layer on the inside of the curve, the blades

will be unbalanced, causing the snowthrower to

“hop” or “bounce.”

Adjusting Carburetor

The carburetor has been factory set, and no

adjustment is required.

2.

Insert the new blade between the rotor halves.

Secure it to the rotor halves with (2) hex–head

capscrews, (2) spacers and (2) lock nuts

(Fig. 24). Position bolt heads on thick (bottom)

side of blade. Curve the blade, and secure it with

the remaining (4) torx screws and lock nuts

(position screw heads on thick side of blade).

Tighten all screws and nuts securely.

Replacing Rotor Blades

Before each snow season, inspect rotor blades for

wear. When blade edge has worn to the wear indicator

hole (Fig. 23), the blades must be replaced to ensure

EN–11

| Categories | Snow Blower Manuals, Toro Snow Blower |

|---|---|

| Tags | Toro 38422, Toro 38424, Toro CCR 2500 |

| Model Number | 9900001 - 9999999 |

| Model Year | 1999 |

| Download File |

|

| Document Type | Operator's Manual |

| Language | English, Français |

| Product Name | Toro CCR 3000 Snowthrower |

| Product Brand | Toro. Customer Service Representatives are available by phone:

Monday - Friday 7:30 a.m. to 9:00 p.m. (CDT) - Saturday 8:00 a.m. to 8:00 p.m. (CDT) - Sunday 10:00 a.m. to 8:00 p.m. (CDT)

Canada 1-888-225-4886 USA 1-888-384-9939, Snow Blower |

| Product Type | Snowthrower |

| Product Series | CCR 1000/2400/2500, Snowthrower |

| Swath | 20 inch |

| Discharge | Single Stage |

| Engine Manufacturer | Toro |

| Engine Oil Type | Toro 2 cycle / NMMA-TCW3 |

| Engine Motor Model # | R-tek |

| Engine Motor Size | 5 hp |

| Engine Motor Type | 2 Cycle EPA1 |

| Document File Type | |

| Publisher | toro.com |

| Wikipedia's Page | Toro Company |

| Copyright | Attribution Non-commercial |

(0 votes, average: 0 out of 5)