2.

(Figs. 27 and 28) (see Drive Belt Covers in this section).

Remove belt covers from both sides of brush shaft

3.

On both sides of machine, remove drive belts from

brush shaft pulleys:

A. Loosen lock nut that secures drive belt idler pul-

ley. Position idler pulley away from drive belt.

B. Carefully remove drive belt from pulley on brush

shaft.

CHOPPER

AXLE

4.

Remove pulley and taper lock bushing from both

ends ofbrush shaft (see Pulley Assembly Service inthis

section).

FRONT

RIGHT

5.

On both sides of machine, remove two (2) flange

nuts and carriage screws that secure side shield (item

toframe.Removeshield,angleplate(item7)andside

skirt plate (item 9) from both sides of machine.

BRUSH

SHAFT

8)

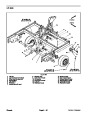

Figure 27

6.

Support brush to prevent it from shifting or falling.

7.

Note location of grease fitting on brush shaft bear-

CHOPPER

AXLE

RIGHT

FRONT

ings so bearings can be properly orientated during

installation. On each side of machine, remove four (4)

carriage screws (item 19), flat washers (item 20) and

lock nuts (item 18) that secure brush shaft flange bear-

ing to brush housing.

8.

remain on the ground. Support Processor to prevent it

from lowering.

Raise Processor while allowing brush assembly to

9.

Remove brush assembly from under machine.

three (3) set screws that secure each flange

BRUSH

SHAFT

10.Loosen

ROTATING

CORNER

SHAFT

bearing to brush shaft. Slide bearings from brush shaft.

Disassemble brush using Figure 29 as a guide.

Installation (Fig. 26)

Assemble brush using Figure 29 as a guide. Apply

JACK

SHAFT

11.

Figure 28

1.

Permatex Blue Gel threadlocker to lower threads of cap

screws (Fig. 29, item 4).

Permatex Blue Gel

Threadlocker

1

2.

Clean both ends of brush shaft and apply a light film

4

of oil to shaft ends.

5

3.

4.

Place brush assembly under raised Processor.

Slowly lower Processor to position brush assembly

to brush housing.

2

3

5.

Slideflangebearingontoeachendofbrushshaft.Do

not tighten set screws in bearings.

Figure 29

1.

2.

3.

Brush (2 used)

Brush drive (4 used)

Washer (4 used)

4.

5.

Cap screw (4 used)

Brush axle

6.

with four (4) carriage screws (item 19), flat washers

(item 20) and lock nuts (item 18).

Align bearing flanges to brush housing and secure

ProCore Processor

Page 6 -- 25

Chassis

| Categories | Lawn Mower Manual, Sprinkler and Irrigation Manuals, Toro Sprinkler and Irrigation Manuals |

|---|---|

| Download File |

|

| Document Type | Catalog |

| Language | English |

| Product Brand | Toro. Customer Service Representatives are available by phone:

Monday - Friday 7:30 a.m. to 9:00 p.m. (CDT) - Saturday 8:00 a.m. to 8:00 p.m. (CDT) - Sunday 10:00 a.m. to 8:00 p.m. (CDT)

Canada 1-888-225-4886 USA 1-888-384-9939, Lawn Mower |

| Document File Type | |

| Publisher | toro.com |

| Wikipedia's Page | Toro Company |

| Copyright | Attribution Non-commercial |

(0 votes, average: 0 out of 5)