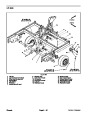

Engine Removal (Fig. 11)

Make sure machine is parked on a level surface with

the engine OFF. Remove key from ignition switch.

Chock wheels to prevent movement of machine. Re-

move spark plug wires from the spark plugs to prevent

the engine from starting unexpectedly.

13.Remove four (4) cap screws, eight (8) flat washers

and lock nuts that secure engine to machine. Note that

negativebatterycableandwireharnessgroundwireare

secured with the front, left corner screw (Fig 12). Also,

at that location, retrieve internal lock washer from be-

tween engine and wire connectors.

1.

IMPORTANT: Make sure to not damage the engine,

fuel hoses, electrical harness or other parts while

removing the engine.

CAUTION

The exhaust system may be hot. Avoid possible

burns,allowexhaust tocoolbeforeremovingthe

engine.

CAUTION

Topreventpersonalinjury,makesurethatengine

is properly supported as it is removed from the

machine. Engine weighs approximately 132

pounds (60 kg).

2.

drain oil from engine before removing engine from ma-

chine.

If engine is to be disassembled, it may be easier to

3.

move negative battery cable first and then the positive

cable.

Disconnect cables from the battery terminals. Re-

14.Carefully

15.Remove

remove the engine from machine.

engine parts and attachments as neces-

sary to repair the engine.

4.

Unplug engine electrical harness connector from

machine wire harness (Fig. 13).

5.

starter motor (Fig. 13).

Disconnect positive cable and fusible link from the

2

1

6.

switch on engine.

Disconnect wire harness connector from ignition

7.

(Fig. 13). Position machine wire harness away from en-

gine.

Loosen screw that secures harness clamp to engine

5

8.

Loosen hose clamp that secures fuel hose to fuel fil-

3

ter inlet (Fig 12). Remove fuel hose from fuel filter. Plug

fuel hose to prevent leakage and contamination. Make

sure to clean up any spilled fuel. Position disconnected

fuel hose away from engine.

4

Figure 12

4.

5.

1.

2.

3.

Hose clamp (filter inlet)

Wire harness ground

Negative battery cable

Fuel filter

Cap screw

9.

Ifnecessary,removeaircleanerfromengine(seeAir

Cleaner Removal in this section).

10.Remove

muffler guard (item 32), beltguard (item 26)

and belt cover (item 30) (see Drive Belt Covers in the

Service and Repairs section of Chapter 6 -- Chassis).

Makesure thattinnerman nuts(items 23and 40)remain

positioned correctly for assembly purposes.

5

2

1

11.

belts from centrifugal clutch and jack shaft pulley.

Loosen drive belt idler pulley. Carefully remove drive

4

3

12.If

necessary, remove centrifugal clutch from engine

crankshaft (see Centrifugal Clutch Removal in this sec-

tion).

Figure 13

1.

2.

3.

Positive battery cable

Fusible link

Engine connector

4.

5.

Wire harness

Harness clamp

ProCore Processor

Page 3 -- 13

Engine

| Categories | Lawn Mower Manual, Sprinkler and Irrigation Manuals, Toro Sprinkler and Irrigation Manuals |

|---|---|

| Download File |

|

| Document Type | Catalog |

| Language | English |

| Product Brand | Toro. Customer Service Representatives are available by phone:

Monday - Friday 7:30 a.m. to 9:00 p.m. (CDT) - Saturday 8:00 a.m. to 8:00 p.m. (CDT) - Sunday 10:00 a.m. to 8:00 p.m. (CDT)

Canada 1-888-225-4886 USA 1-888-384-9939, Lawn Mower |

| Document File Type | |

| Publisher | toro.com |

| Wikipedia's Page | Toro Company |

| Copyright | Attribution Non-commercial |

(0 votes, average: 0 out of 5)