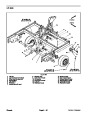

Removal (Fig. 19)

Have ProCore Processor attached to tow vehicle

and park both machines on a level surface. Secure lift

axle to frame with hitch pin and lynch pin to prevent lift

axle from shifting.

Installation (Fig. 19)

1.

1. If removed, install fittings with new O--rings into lift

cylinder ports (see Hydraulic Fitting Installation in the

General Information section of this chapter).

2.

Position lift cylinder to the machine mounting points.

2.

Engage vehicle parking brake, stop engine and re-

Make sure the lift cylinder fittings face the front of the

machine.

move key from the ignition switch. Make sure that Pro-

Core Processor engine is off. Chock wheels to prevent

movement of either machine.

IMPORTANT: Whensecuringpivotpinstoframe,do

not overtighten shoulder bolts. There should be

clearance between the shoulder bolt head and pivot

pin.

3.

Loosen straps that secure fuel tank to machine

frame (see Fuel Tank Removal in the Service and Re-

pairs section of Chapter 3 -- Engine). Shift tank position

toward right side of machine to allow access to lift cylin-

der pivot pins, fittings and hydraulic hoses.

3.

Install pivot pins. Secure pivot pins to frame with shoul-

der bolts.

Align lift cylinder mounting holes with frame mounts.

4.

5.

draulic fittings on lift cylinder. Tighten hose connections

(see Hydraulic Hose and Tube Installation in the Gener-

al Information section).

Removeplugsfromdisconnected hoses andfittings.

Connect hydraulic hoses with new O--rings to hy-

CAUTION

Operate all hydraulic controls to relieve system

pressure and to avoid injury from pressurized

hydraulic oil. See Relieving Hydraulic System

Pressure in the General Information section of

this chapter.

6.

Return fuel tank to correct position and secure to

frame with straps and fasteners (see Fuel Tank Installa-

tion in the Service and Repairs section of Chapter 3 --

Engine).

4.

5.

Relieve hydraulic system pressure.

Label hydraulic hose positions for assembly pur-

7.

Lubricate grease fittings on lift cylinder pivot pins.

poses.

8.

Operate machine functions slowly until air is out of

6.

Disconnecthydraulichosesfromhydraulicfittingson

Core Processor hydraulic system.

Check oil level in tow vehicle hydraulic reservoir and

liftcylinder(Fig.20).LocateanddiscardO--ringfrombe-

tweenhosesandfittings.Allowhosestodrainintoasuit-

able container.

9.

add correct oil if necessary.

7.

Plug disconnected hoses and fittings to prevent con-

tamination.

2

8.

tain lift cylinder pivot pins (item 6) to machine frame.

Remove shoulder bolts (item 8) that are used to re-

5

9.

Support lift cylinder and slide pivot pins from the lift

1

cylinder and machine frame.

10.Remove

lift cylinder from the machine.

3

4

11.

If needed, remove fittings and O--rings from the lift

cylinder (Fig. 20). Discard O--rings.

12.Inspect

or damage. Replace bushing if necessary.If bushing re-

placement is necessary, position bushing as follows:

bushing in axle and frame (item 13) for wear

6

2

A. Bushing in frame position should be installed so

bushing split is orientated toward front of frame.

Figure 20

1.

2.

3.

Lift cylinder

4.

5.

6.

O--ring

Hydraulic hose

Hydraulic hose

B. Bushing in lift axle position should be installed so

bushing split is orientated toward lift axle.

O--ring

90o hydraulic fitting

ProCore Processor

Page 4 -- 25

Hydraulic System

| Categories | Lawn Mower Manual, Sprinkler and Irrigation Manuals, Toro Sprinkler and Irrigation Manuals |

|---|---|

| Download File |

|

| Document Type | Catalog |

| Language | English |

| Product Brand | Toro. Customer Service Representatives are available by phone:

Monday - Friday 7:30 a.m. to 9:00 p.m. (CDT) - Saturday 8:00 a.m. to 8:00 p.m. (CDT) - Sunday 10:00 a.m. to 8:00 p.m. (CDT)

Canada 1-888-225-4886 USA 1-888-384-9939, Lawn Mower |

| Document File Type | |

| Publisher | toro.com |

| Wikipedia's Page | Toro Company |

| Copyright | Attribution Non-commercial |

(0 votes, average: 0 out of 5)