Chopper tips and blade assemblies can be removed

and installed with the chopper axle mounted in the ma-

chine.

270

to 330 in--lb

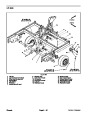

Disassembly (Figs. 16 and 17)

(31 to 37 N--m)

1.

Park ProCore Processor on a level surface with the

Processor fully lowered. Make sure that Processor en-

gine is off. Remove key from the ignition switch. Chock

wheels to prevent movement of the machine.

3

2

1

NOTE: The RH and LH blade assembly use the same

blade but differ in which holes are used to mount the

chopper tip to the blade (Fig. 18). Blades that have the

chopper tips mounted toward the right side of the ma-

chine are RH assemblies. Blades that have the chopper

tips mounted toward the left side of the machine are LH

assemblies (shown in Fig. 17). Before removing chop-

per tip from blade, note which blade holes are used for

proper attachment of chopper tip.

2

Figure 17

1.

2.

Blade (LH shown)

3.

Chopper tip

Screw with patch lock

NOTE: The screws used to secure chopper tip to blade

have a patch lock. To ease screw removal, apply heat to

thread area of chopper tip while removing screw.

2

NOTE: If a screw used to secure chopper tip to blade

has broken, remove chopper blade from chopper axle.

Make a slot in the screw end that protrudes beyond the

chopper tip.Apply heatto thread area ofchopper tipand

useaflatbladescrewdriver toremovethebrokenscrew.

3

2.

ing box wrench to remove two (2) screws that secure tip

to blade.

To remove chopper tip(s) from blade, use a ratchet-

1

3.

To remove chopper blades from chopper axle, re-

2

move two (2) cap screws and lock nuts that secure right

and left blade assemblies to axle. Remove blade as-

semblies. Note that notch on both blades align (Fig. 18).

3

Assembly (Figs. 16 and 17)

4

1.

threads in tip(s) with a 5/16 -- UNC tap.

Inspect threads of chopper tip(s). If necessary, clean

Figure 18

1.

2.

Blade

Holes for RH blade

3.

4.

Holes for LH blade

Alignment notch

IMPORTANT: Due to the patch lock feature of the

screws usedtosecure thechopper tipstotheblade,

itisrecommendedtoreplacethescrewsafterdisas-

sembly. An alternative would be to apply Loctite

#242

(or equivalent) to the threads of the original

screws before assembly.

2.

Secure chopper tip(s) to correct holes of chopper

blade with two (2) screws. Torque screws from 270 to

in--lb (31 to 37 N--m).

330

3.

Ifbladeswereremoved fromaxle,secureRHandLH

chopper blades to chopper axle with two (2) cap screws

andlocknuts.Makesure thatnotch onboth blades align

(Fig. 18).

ProCore Processor

Page 6 -- 19

Chassis

| Categories | Lawn Mower Manual, Sprinkler and Irrigation Manuals, Toro Sprinkler and Irrigation Manuals |

|---|---|

| Download File |

|

| Document Type | Catalog |

| Language | English |

| Product Brand | Toro. Customer Service Representatives are available by phone:

Monday - Friday 7:30 a.m. to 9:00 p.m. (CDT) - Saturday 8:00 a.m. to 8:00 p.m. (CDT) - Sunday 10:00 a.m. to 8:00 p.m. (CDT)

Canada 1-888-225-4886 USA 1-888-384-9939, Lawn Mower |

| Document File Type | |

| Publisher | toro.com |

| Wikipedia's Page | Toro Company |

| Copyright | Attribution Non-commercial |

(0 votes, average: 0 out of 5)