7.

Rotate brush a few times and center brush in frame.

Raise Processor so that brush is slightly off ground.

1

FRONT

8.

Secure brush shaft in bearings (see Flange Bearing

Service in this section).

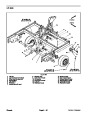

NOTE: Chopper tip orientation

in relation to brush housing

9.

Rotate chopper axle so that a row of chopper tips is

aligned with the brush housing corner. Rotate brush

shaft so that one of the brush tips is aligned with the ro-

tating corner shaft (Fig. 30).

IMPORTANT: When installing pulleys and drive

belts, make sure to properly align drive, driven and

idler pulleys.

3

NOTE: When installing pulley on right end of brush

shaft, align pulley and drive belt with drive pulley on

chopper axle.

2

CHOPPER AXLE TO

BRUSH ORIENTATION

NOTE: Brush orientation

in relation to rotating

corner shaft

IMPORTANT: Make sure that brush shaft and chop-

per axle are properly aligned as drive belt is

installed on right end of brush shaft (Fig. 30). Im-

proper alignment will decrease machine perfor-

mance and may lead to increased debris buildup in

Processor that can cause accelerated component

wear and damage.

Figure 30

1.

2.

Chopper axle

Brush shaft

3.

Rotating corner shaft

3

1

2

10.Install

square key, pulley, taper lock bushing and

drive belt to right end of brush shaft (see Pulley Assem-

bly Service in this section).

NOTE: Wheninstalling pulley onleftendofbrushshaft,

align pulley and drive belt with driven pulley on rotating

corner shaft.

0.050”

(1.3 mm)

UP

11.

Install square key, pulley, taper lock bushing and

Idler Face to Sheave Face

drive belt to left end of brush shaft (see Pulley Assembly

Service in this section).

Figure 31

3. Idler pulley

1.

2.

Brush shaft

Chopper axle

12.Adjust

drive belt idler pulleys to achieve proper ten-

sion on drive belts (see Operator’s Manual). After ad-

justment, make sure that chopper axle and brush shaft

are still properly aligned (Fig. 30).

IMPORTANT: After adjusting belt tension, check

that distance from idler pulley face to the faces of

the drive and driven pulleys is correct (Figs. 31 and

1

3

2

32).

This distance is necessary to ensure that idler

pulley is correctly aligned to drive belts. If neces-

sary, re--adjust positions of drive and driven pulleys

to allow correct distance.

13.Secure

side shield (item 8), angle plate (item 7) and

side skirt plate (item 9) to each side of machine with two

flange nuts and carriage screws.

Idler Face and Sheave Faces

in Alignment

UP

(2)

Figure 32

14.Install

tion).

belt covers (see Drive Belt Covers in this sec-

1.

2.

Brush shaft

3. Idler pulley

Rotating corner shaft

Chassis

Page 6 -- 26

ProCore Processor

| Categories | Lawn Mower Manual, Sprinkler and Irrigation Manuals, Toro Sprinkler and Irrigation Manuals |

|---|---|

| Download File |

|

| Document Type | Catalog |

| Language | English |

| Product Brand | Toro. Customer Service Representatives are available by phone:

Monday - Friday 7:30 a.m. to 9:00 p.m. (CDT) - Saturday 8:00 a.m. to 8:00 p.m. (CDT) - Sunday 10:00 a.m. to 8:00 p.m. (CDT)

Canada 1-888-225-4886 USA 1-888-384-9939, Lawn Mower |

| Document File Type | |

| Publisher | toro.com |

| Wikipedia's Page | Toro Company |

| Copyright | Attribution Non-commercial |

(0 votes, average: 0 out of 5)