Battery Service

The battery is the heart of the electrical system. With

regular andproper service, battery lifecan beextended.

Additionally, battery and electrical component failure

can be prevented.

2

3

CAUTION

When working with batteries, use extreme cau-

tion to avoid splashing or spilling electrolyte.

Electrolyte can destroy clothing and burn skin

and eyes. Always wear safety goggles and a face

shield when working with batteries.

1

Electrolyte Specific Gravity

Fully charged: 1.265 corrected to 80oF (26.7oC)

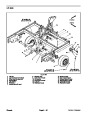

Figure 16

Discharged: less than 1.240

1.

2.

Battery

Positive battery cable

3.

Negative battery cable

Battery Specifications

BCI Group Size 28

535

Reserve Capacity of 110 minutes at 80oF (27oC)

Inspection, Maintenance and Testing

CCA at 0o F (--18o C)

1.

Perform the following inspections and maintenance:

Dimensions (including terminal posts)

Length

Width

Height

10.3 inches (262 mm)

6.8 inches (173 mm)

9.5 inches (241 mm)

A. Check battery case for cracks. Replace battery if

cracked or leaking.

Removal and Installation (Fig. 16)

B. Checkbatteryterminalsforcorrosion.Ifcorrosion

occurs at terminals, disconnect cables. Always dis-

connect negative (--) cable first. Clean cable clamps

and battery terminals separately. Reconnect cables

with positive (+) cable first. Coat battery posts and

cable connectors with Battery Terminal Protector

(Toro Part No. 107--0392) or petroleum jelly to pre-

vent corrosion.

1.

OFF position. Remove key from the ignition switch.

Loosen strap and remove battery box cover.

Make sure that Processor ignition switch is in the

2.

ter negative cable has been removed, loosen and re-

move positive cable from battery.

Loosen and remove negative cable from battery. Af-

IMPORTANT: Before cleaning the battery, tape

or block vent holes to the filler caps and make

sure the caps are on tightly.

3.

4.

Carefully remove battery from machine.

Install battery in reverse order making sure to con-

nect and tighten positive cable to battery before con-

necting negative cable. Tighten nuts that secure battery

cables from 10 to 15 ft--lb (14 to 20 N--m).

C. Check for signs of wetness or leakage on the top

ofthe battery which mightindicate aloose ormissing

filler cap, overcharging, loose terminal post or over-

filling. Also, check battery case for dirt and oil. Clean

the battery with a solution of baking soda and water,

then rinse it with clean water.

NOTE: Before connecting the negative (ground) cable

to the battery, connect a digital multimeter (set to DC

Amps) between the negative battery post and the nega-

tive (ground) cable connector. The reading should be

less than 0.1 amp. If the reading is 0.1 amp or more, the

machine’s electrical system should be tested for short

circuits or faulty components and repaired.

D. Check thatthe cover seal is notbroken away.Re-

place the battery if the seal is broken or leaking.

E. Check theelectrolyte levelineachcell.Ifthelevel

is below the tops of the plates in any cell, fill all cells

with distilled water between the minimum and max-

imum fill lines. Charge at 15 to 25 amps for 15 min-

utes to allow sufficient mixing of the electrolyte.

5.

Install battery box cover and secure with strap.

ProCore Processor

Page 5 -- 13

Electrical System

| Categories | Lawn Mower Manual, Sprinkler and Irrigation Manuals, Toro Sprinkler and Irrigation Manuals |

|---|---|

| Download File |

|

| Document Type | Catalog |

| Language | English |

| Product Brand | Toro. Customer Service Representatives are available by phone:

Monday - Friday 7:30 a.m. to 9:00 p.m. (CDT) - Saturday 8:00 a.m. to 8:00 p.m. (CDT) - Sunday 10:00 a.m. to 8:00 p.m. (CDT)

Canada 1-888-225-4886 USA 1-888-384-9939, Lawn Mower |

| Document File Type | |

| Publisher | toro.com |

| Wikipedia's Page | Toro Company |

| Copyright | Attribution Non-commercial |

(0 votes, average: 0 out of 5)