Troubleshooting

Studying the operating characteristics preceding an

electrical failure will help in identifying the area of diffi-

culty. Try to isolate the failure to a specific functional

system; then check that area, repairing one component

at a time. Attempting to repair two systems at once will

lead to confusion.

CAUTION

Remove all jewelry, especially rings and

watches, before doing any electrical trou-

bleshooting. Disconnect battery cables un-

less the test requires battery voltage.

NOTE: The interlock switches are described as nor-

mally open (NO) or normally closed (NC). The NC-NO

description indicates the switch contact position with the

switch installed in the machine with MOW OFF,

TRANSMISSION in NEUTRAL, and OPERATOR OFF

of seat. Should the machine being repaired have these

components by-passed, they should be reconnected for

proper troubleshooting and safety.

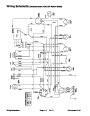

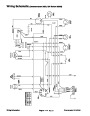

For effective troubleshooting and repairs, you must

have a good understanding of the electrical circuits and

components used. Tools such as a volt/ohm multimeter

will help find problems in the circuitry.

Condition

Cause

Correction

1. Engine starts (but should not)

when shift selector is in gear.

Traction switch adjusted incorrectly

or is malfunctioning.

Adjust or replace traction switch.

2. Engine starts (but should not)

when mow pedal is depressed

(reels engaged).

Mow/lift switch adjusted incorrectly

or is malfunctioning.

Adjust or replace mow/lift switch.

3. Engine fails to crank, regard-

less of shift selector or mow

pedal position.

Mow/lift switch and/or traction

switch out of adjustment or mal-

functioning.

Adjust or replace traction switch

and/or mow/lift switch.

Loose or corroded battery connec-

tions.

Clean and tighten connections.

Mow/lift switch or traction switch

wires are loose.

Check wires and connect prop-

erly.

Battery is dead.

Charge or replace battery.

Replace solenoid.

Starter solenoid is malfunctioning.

Ignition switch is malfunctioning.

Starter is malfunctioning.

Engine is seized.

Replace ignition switch.

Replace or repair starter.

Repair engine.

Key switch, ammeter or solenoid

wires loose.

Connect wires.

4. Engine fails to crank with con-

trols in “neutral” when operator is

off seat, but does crank when op-

erator is on seat.

Wiring harness connected wrong.

Wiring harness malfunctioning.

Connect wiring harness correctly:

refer to Electrical Schematic.

Install new wiring harness.

Troubleshooting

Page 5 - 6

Greensmaster® 3100

| Categories | Lawn Mower Manual, Sprinkler and Irrigation Manuals, Toro Sprinkler and Irrigation Manuals |

|---|---|

| Tags | Toro Groundsmaster 3050, Toro Groundsmaster 3100 |

| Download File |

|

| Document Type | Catalog |

| Language | English |

| Product Brand | Toro. Customer Service Representatives are available by phone:

Monday - Friday 7:30 a.m. to 9:00 p.m. (CDT) - Saturday 8:00 a.m. to 8:00 p.m. (CDT) - Sunday 10:00 a.m. to 8:00 p.m. (CDT)

Canada 1-888-225-4886 USA 1-888-384-9939, Lawn Mower |

| Document File Type | |

| Publisher | toro.com |

| Wikipedia's Page | Toro Company |

| Copyright | Attribution Non-commercial |

(0 votes, average: 0 out of 5)