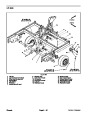

Installation (Fig. 19)

IMPORTANT: Make sure that brush shaft and

chopper axle are properly aligned as drive belt is

installed (Fig. 23). Improper alignment will de-

crease machine performance and may lead to in-

creased debris buildup in Processor that can

cause accelerated component wear and dam-

age.

CAUTION

To prevent personal injury, make sure that chop-

per assembly is properly supported as it is

installed to the machine. Chopper assembly

weighs approximately 125 pounds (57 kg).

C. Rotate chopper axle so that a row of chopper tips

is aligned with the brush housing corner. Rotate

brush shaft so that one of the brush tips is aligned

with the rotating corner shaft (Fig. 23).

1.

Install chopper assembly into machine from the rear

of the machine. Clean chopper axle ends and apply a

light film of oil to shaft ends.

D. After positioning chopper axle and brush shaft,

installdrivebelttosprocketonchopperaxleanddriv-

en pulley on brush shaft. Keep shafts properly

aligned as drive belt is installed.

2.

On both sides of machine, install bearing and end-

plate:

NOTE: Whenpositioningpulleyontotherightendof

chopper axle, align pulley and belt with driven pulley

on brush shaft.

A. If removed, attach bearing to endplate with four

(4) carriage screws, flat washers and lock nuts.

B. Slide endplate with bearing onto chopper axle.

E. Using astraightedgeacrossthefaceofthebrush

shaft driven pulley, move sprocket on chopper axle

so that drive belt and straight edge are aligned indi-

cating correct position of sprocket.

C. Align holes in endplate and machine frame. Se-

cure endplate in position with seven (7) carriage

screws and flange nuts.

3.

chopper between bearings. Secure chopper axle in

bearings (see Flange Bearing Service in this section).

Rotate chopper assembly a few times and center

F. Apply Loctite #242 (or equivalent) to threads of

set screws (item 15). Install and tighten set screws

into sprocket to secure sprocket to chopper axle.

4.

and secure with removed fasteners (Fig. 22).

Position reinforcing ring (item 8) to chopper housing

FRONT

1

IMPORTANT: When installing pulleys and drive

belts, make sure to properly align drive, driven and

idler pulleys.

NOTE: Chopper tip orientation

in relation to brush housing

NOTE: When installing pulley on left end of chopper

axle,alignpulley anddrivebelts with drivepulley onjack

shaft.

5.

drivebeltstoleftendofchopperaxle(seePulleyAssem-

bly Service in this section).

Install square key, pulley, taper lock bushing and

3

6.

of chopper axle:

Installsquarekey,sprocketanddrivebelttorightend

2

A. Apply antiseize lubricant to square key and place

key in chopper axle slot.

CHOPPER AXLE TO

BRUSH ORIENTATION

NOTE: Brush orientation

in relation to rotating

corner shaft

Figure 23

B. Slide sprocket onto chopper axle. Do not tighten

set screws in sprocket.

1.

2.

Chopper axle

Brush shaft

3.

Rotating corner shaft

Chassis

Page 6 -- 22

ProCore Processor

| Categories | Lawn Mower Manual, Sprinkler and Irrigation Manuals, Toro Sprinkler and Irrigation Manuals |

|---|---|

| Download File |

|

| Document Type | Catalog |

| Language | English |

| Product Brand | Toro. Customer Service Representatives are available by phone:

Monday - Friday 7:30 a.m. to 9:00 p.m. (CDT) - Saturday 8:00 a.m. to 8:00 p.m. (CDT) - Sunday 10:00 a.m. to 8:00 p.m. (CDT)

Canada 1-888-225-4886 USA 1-888-384-9939, Lawn Mower |

| Document File Type | |

| Publisher | toro.com |

| Wikipedia's Page | Toro Company |

| Copyright | Attribution Non-commercial |

(0 votes, average: 0 out of 5)