2.

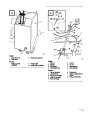

Tighten machine screw and locknut on left side

until chute retainer plate is positioned against

plastic chute retainer and discharge chute is

secured to chute ring.

2.

3.

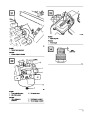

Move the snowthrower onto a flat surface and

check if scraper (Fig. 8) is parallel to the ground.

If not, adjust scraper; refer to Adjusting Scraper,

page 17.

3.

4.

Push chute retainers on right side toward

discharge chute (slotted) and tighten machine

screw.

Remove (2) flange bolts and washers securing

ends of scraper to side plates (Fig. 9). Reinstall

bolts through rear slots in skids. Assemble both

skids so that washers are between skids and

sideplates (Fig. 9). Do not tighten bolts.

Make sure chute rotates freely on ring. If chute

binds, move right hand retainer outward to ease

operation.

4.

Install (2) flange bolts through front slots in

skids and thru sideplates. Install flat washers and

locknuts on inside of sideplates. Do not tighten

bolts.

Install Chute Control Gear

(Fig. 7)

Note:

The following steps adjust the skids for

paved surfaces. For gravel or crushed

rock surfaces, refer to Adjusting Skids,

page 17.

1.

2.

3.

Insert the 5/16-18 x 1” lg. carriage bolt into gear

bracket mounting hole.

Position worm gear into bracket, align holes and

insert chute gear rod through bracket and gear.

5.

6.

Manually move wheels to the rear Power Shift

position by lifting up on handles and moving the

shift control fully forward to Power Shift

position (Fig. 10).

Loosely mount worm gear and bracket to

mounting flange with carriage bolt, flat washer,

and locknut.

Support the scraper to be 1/8 inch above a level

surface if the snowthrower is to be used on

smooth pavement.

4.

5.

Slide worm gear into teeth of chute gear and

tighten locknut.

Note:

The scraper should be higher than 1/8

inch above the pavement if the

pavement surfaces are cracked, rough

or uneven.

Check operation. Move gear slightly outward if

binding is evident.

Check Tire Pressure

7.

Move the skids down to sit flat on the ground

and tighten the (4) flange bolts securing both

skids to the auger side plates.

IMPORTANT: Check pressure of tires

because they are over-inflated at the factory

for shipping. Therefore, before the

snowthrower is operated, reduce pressure in

both tires to 7-15 psi equally.

Check Auger Gear Box Oil

1.

2.

3.

4.

Move snowthrower to a level surface.

Install Skids

Clean area around pipe plug so dirt is removed.

Remove pipe plug from gear box (Fig. 11).

1.

Check tire pressure; refer to Check Tire Pressure,

page 12.

Check oil level in gear box. Oil must be at point

of overflowing in filler opening.

GB–12

| Categories | Snow Blower Manuals, Toro Snow Blower |

|---|---|

| Tags | Toro 1028 Power Shift, Toro 38558, Toro 38559 |

| Model Number | 38559 |

| Model Year | 1999 |

| Download File |

|

| Document Type | Operator's Manual |

| Language | Français |

| Serial Number | 99000001 - 99999999 |

| Product Name | Toro 1028 Power Shift Snowthrower |

| Product Brand | Toro. Customer Service Representatives are available by phone:

Monday - Friday 7:30 a.m. to 9:00 p.m. (CDT) - Saturday 8:00 a.m. to 8:00 p.m. (CDT) - Sunday 10:00 a.m. to 8:00 p.m. (CDT)

Canada 1-888-225-4886 USA 1-888-384-9939, Snow Blower |

| Product Type | Snowthrower |

| Product Series | Snowthrower, Two Stage Power Shift |

| Swath | 21 inch |

| Discharge | Two Stage |

| Engine Manufacturer | Tecumseh |

| Engine Oil Type | 26 oz. (.8l) 5w-30 or 10w / API SH or higher |

| Gearbox Lubricant | 4.5 oz. (133ml) SAE 90 GL5 or higher |

| Engine Motor Model # | OHSK100-221607A |

| Engine Motor Size | 10 hp |

| Engine Motor Type | 4 Cycle CARB1, EPA1 |

| Transmission Speed | 4 Forward/2 Reverse |

| Transmission Type | Gear |

| Document File Type | |

| Publisher | toro.com |

| Wikipedia's Page | Toro Company |

| Copyright | Attribution Non-commercial |

(0 votes, average: 0 out of 5)