Operation

The crankarm used in the #1 crankshaft position is in-

corporated into the driven pulley. Crankarms used in

crankshaft positions #2 and #4 are the same compo-

nent. These crankarms can be identified with the num-

bers 2, 4 and 6 in the crankarm castings. Crankarms

used in crankshaft positions #3 and #5 use the same

crankarm and can be identified with the numbers 3 and

The ProCore 1298 is comprised of two (2) independent

coring heads connected with a pivoting subframe sys-

tem. Each of the coring heads includes a coring crank-

shaft assembly, turf holders, tine holders and aerating

tines. The crankshaft assembly operates six (6) stomper

arms with rotolink assemblies to provide vertical tine

motion. The coring head frame pivots to allow aerating

depth control.

5

in the castings. The crankarm used in crankshaft posi-

tion #6 is different than other crankarms and has the

numbers 2, 4 and 6 in the casting.

Drive for the dual coring heads comes from the tow trac-

tor PTO. A single gearbox on the ProCore is turned by

a driveshaft connected to the tractor PTO. The gearbox

provides rotation for the two (2) coring head crankshaft

assemblies.

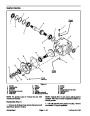

Two (2) coupler assemblies are used to connect the

crankarms that are secured in the bearing housings.

These coupler assemblies use two (2) couplings, a cou-

pling plate, two (2) iso−mounts and necessary fasten-

ers. The couplings used on the ProCore 1298 are all

different. The couplings are identified with the crank-

shaft position in the coupling casting.

The ProCore gearbox rotates two (2) driveshafts. Each

of these driveshafts rotates a coring head crankshaft

with a pulley and 4 groove drive belt tensioned by a

spring loaded idler pulley.

The stomper arms and rotolink assemblies used on the

ProCore 1298 are the same for all crankshaft positions.

The two (2) coring crankshafts are composed of multiple

crankarms, bearings, bearing housings and couplings.

For assembly purposes, proper crankshaft component

position is identified by alignment marks on bearing

housings and numbers cast into crankarms and cou-

pling components. Crankarm journals are timed to en-

sure minimal vibration.

Coring Crankshaft Timing

When properly assembled, the crankshaft position num-

bers on the crankarms will align with the raised align-

ment marks on the bearing housing (Fig. 3). The timing

of either coring head is not dependent on the adjacent

coring head.

Aeration depth control is performed by adjusting the cor-

ing head depth control assembly to obtain the desired

aerating depth.

2

Turf holders are used to prevent damage to the turf as

the tines are lifted from the ground.

1

1

A variety of tines, tine heads and turf holders are avail-

able for use on the ProCore 1298. See the Operator’s

Manual for available options.

2

Coring Crankshaft (Fig. 2)

2

Each of the ProCore 1298 coring crankshaft assemblies

is composed of six (6) crankarms. The crankarms are

timed for proper aerating operation. Coring crankshaft

positions are identified based on their relationship with

the crankshaft driven pulley. The #1 position is at the

pulley side of the crankshaft (Fig. 2).

Figure 3

1.

Housing timing mark

2. Crankarm position

The crankshaft assembly on each of the coring heads is

supported with three (3) identical bearing housing as-

semblies. Each bearing housing supports two (2) cran-

karms.

ProCore 864/1298

Page 4 − 7

Coring Head

| Categories | Lawn Mower Manual, Sprinkler and Irrigation Manuals, Toro Sprinkler and Irrigation Manuals |

|---|---|

| Tags | Toro ProCore 1298, Toro ProCore 864 |

| Download File |

|

| Document Type | Catalog |

| Language | English |

| Product Brand | Toro. Customer Service Representatives are available by phone:

Monday - Friday 7:30 a.m. to 9:00 p.m. (CDT) - Saturday 8:00 a.m. to 8:00 p.m. (CDT) - Sunday 10:00 a.m. to 8:00 p.m. (CDT)

Canada 1-888-225-4886 USA 1-888-384-9939, Lawn Mower |

| Document File Type | |

| Publisher | toro.com |

| Wikipedia's Page | Toro Company |

| Copyright | Attribution Non-commercial |

(0 votes, average: 0 out of 5)