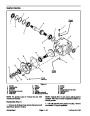

Disassembly (Fig. 34)

Remove flange head screw (item 1), flat washer

3. Position worm gear assembly into depth control hub.

Slide plain washer (item 19) between worm gear and

control hub.

1.

(item 2) and depth control gage (item 3) from top of

depth control shaft.

4. Place inner flange bushing (item 11) into depth con-

trol hub.

2.

Remove hairpin clip (item 9) and shoe (item 8) from

bottom of depth control shaft.

5. Install components onto adjustment shaft (item 25):

3.

from depth control hub.

Unscrew depth control shaft (item 10) and remove

A. Slide outer flange bushing (item 11), worm gear

spacer (item 15), thrust washer (item 13), greased

thrust bearing (item 12) and second thrust washer

onto shaft.

4.

Remove upper and lower oil seals (items 4 and 7)

from depth control hub. Take care to not damage seal

bores in hub. Discard seals.

B. Place key (item 24) into shaft slot, align worm

(item 14) with key and then slide greased worm onto

shaft.

5.

Remove six (6) flange head screws (item 23) that se-

cure lock plate and cover to depth control hub. Remove

lock plate, cover and gasket.

C. Place thrust washer (item 13), greased thrust

bearing (item 12) and final thrust washer onto shaft.

6.

Slide adjustment shaft assembly from depth control

hub. Remove flange bushings (item 11), thrust washers

(item 13), thrust bearings (item 12), worm (item 14), key

(item 24) and worm gear spacer (item 15) from adjust-

ment shaft.

6. Slide assembled adjustment shaft into inner flange

bushing in depth control hub. Make sure that inner

flange bushing is still properly positioned in hub bore.

7.

Place gasket (item 20) and cover (item 21) onto

7.

hub.

Remove plain washer (item 19) from depth control

depth control hub. Make sure that outer flange bushing

(item 11) is properly positioned into cover bore. Install

four (4) flange head screws that surround adjustment

shaft. Do not fully tighten screws at this time.

8.

Slide worm gear (item 18) with two (2) bearing wash-

ers (item 16) and thrust bearing (item 17) from depth

control hub. Remove bearing washers and thrust bear-

ing from worm gear flange.

8. Lightly oil upper and lower oil seals. Install seals into

depth control hub taking care to not damage seals dur-

ing installation.

9.

Clean and inspect all components. Replace all com-

ponents that are worn or damaged.

9. Insert greased depth control shaft (item 10) into bot-

tom of depth control hub and thread shaft into worm

gear. Take care to not damage seals during depth con-

trol shaft installation.

Assembly (Fig. 34)

1.

Apply grease to depth control components:

10.Position

two (2) flange head screws. Fully tighten all six (6) cover

screws.

lock plate (item 22) to cover and secure with

A. Pack thrust bearings (items 12 and 17) 60% to

100%

full with grease.

B. Fill all threads of depth control shaft (item 10)

60% to 100% full with grease.

11.

and secure with hairpin clip.

Place shoe (item 8) on bottom of depth control shaft

C. Fill all gear teeth voids of worm (item 14) and

worm gear (item 18) 60% to 100% full with grease.

12.Position

depth control gage (item 3) to top of depth

control shaft and align slot in gage with tab on shaft. Se-

cure gage to control shaft with flat washer and flange

head screw.

2.

Place bearing washer (item 16), greased thrust bear-

ing (item 17) and then second bearing washer onto

flange of greased worm gear (item 18).

ProCore 864/1298

Page 4 − 35

Coring Head

| Categories | Lawn Mower Manual, Sprinkler and Irrigation Manuals, Toro Sprinkler and Irrigation Manuals |

|---|---|

| Tags | Toro ProCore 1298, Toro ProCore 864 |

| Download File |

|

| Document Type | Catalog |

| Language | English |

| Product Brand | Toro. Customer Service Representatives are available by phone:

Monday - Friday 7:30 a.m. to 9:00 p.m. (CDT) - Saturday 8:00 a.m. to 8:00 p.m. (CDT) - Sunday 10:00 a.m. to 8:00 p.m. (CDT)

Canada 1-888-225-4886 USA 1-888-384-9939, Lawn Mower |

| Document File Type | |

| Publisher | toro.com |

| Wikipedia's Page | Toro Company |

| Copyright | Attribution Non-commercial |

(0 votes, average: 0 out of 5)