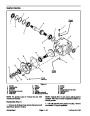

Disassembly (Fig. 29)

Position aerator on a firm, level surface. If attached

to tractor, disengage PTO, apply tractor parking brake,

stop engine and remove key from the ignition switch.

7. Using suitable lift or hoist, raise coring head slightly

using lifting eyelets on coring crankshaft as lift points

(Fig. 30). Use appropriate jackstands or blocking to sup-

port the coring head to prevent it from shifting.

1.

8.

frame and coring head frame.

Remove upper link assemblies (item 21) from hitch

2.

head depth to the deepest setting.

Remove rear hood from machine. Adjust coring

9.

of pivot shafts to machine.

Remove fasteners (items 4, 5 and 6) that secure end

3.

Remove front cover and pulley shield from machine

(see Cover Removal in the Service and Repairs section

of Chapter 3 − Chassis).

10.Carefully slide pivot shafts from H−frame. Locate

and retrieve four (4) thrust washers (item 2) from be-

tween H−frame and machine frame.

4.

Support the aerator to prevent the machine from

moving.

11.

Remove H−frame from machine.

NOTE: The ProCore 1298 uses one (1) compression

spring for each of its dual coring frames. The ProCore

12.If necessary, remove bushings (item 20) from H−

frame.

864

uses two (2) compression springs for its single cor-

ing frame.

2

WARNING

THE CORING HEAD FRAME IS SPRING LOADED!

To prevent possible personal injury, use com-

pression spring tool (see Special Tools) to re-

move compression spring(s) before disassem-

bling the coring head pivot.

1

5.

Use compression spring tool (see Special Tools) to

remove compression spring(s) from coring head frame:

A. Install compression spring tool threaded rod

through holes in each spring cup (item 1), then install

washer and nut on both ends of rod.

Figure 30

1.

Bearing housing

2. Lifting eyelet

B. Tighten upper nut on rod to compress spring

(item 2).

Assembly (Fig. 29)

If upper links were disassembled, note that link has

1.

C. With tool compressing the spring, carefully lift

bottom of spring, slide it from coring head frame, low-

er from hitch frame and remove from machine.

a groove on the end that has left hand threads. Install rod

ends equally to make link assembly from 8.170” to

8.230”

(208 to 209 mm) long (rod center to rod center)

(Fig. 31). Also, align rod ends before tightening jam

nuts.

D. If working on ProCore 864, repeat for second

compression spring.

2.

bushings into H−frame bores. Bushings should be re-

cessed into the H−frame at least 0.030” (0.8 mm).

If bushings were removed from H−frame, press new

6.

stands or blocking.

Make sure that machine is well supported with jack-

IMPORTANT: When installing pivot shafts, make

sure that both sides of H−frame are aligned with

holes in frame before installing pivot shaft.

CAUTION

The ProCore 864 coring head frame assembly

weighs approximately 900 pounds (408 kg). The

ProCore 1298 coring head frame assembly

weighs approximately 675 pounds (306 kg).

Make sure that proper lift or hoist is used to sup-

port coring head frame during repairs.

3.

Position H−frame to hitch frame making sure that

thrust washers are placed between H−frame and hitch

frame. Align both sides of H−frame to pivot shaft holes

in hitch frame. Slide pivot shaft through hitch frame and

H−frame. Secure pivot shaft to hitch frame with cap

screw and flange nut.

ProCore 864/1298

Page 4 − 29

Coring Head

| Categories | Lawn Mower Manual, Sprinkler and Irrigation Manuals, Toro Sprinkler and Irrigation Manuals |

|---|---|

| Tags | Toro ProCore 1298, Toro ProCore 864 |

| Download File |

|

| Document Type | Catalog |

| Language | English |

| Product Brand | Toro. Customer Service Representatives are available by phone:

Monday - Friday 7:30 a.m. to 9:00 p.m. (CDT) - Saturday 8:00 a.m. to 8:00 p.m. (CDT) - Sunday 10:00 a.m. to 8:00 p.m. (CDT)

Canada 1-888-225-4886 USA 1-888-384-9939, Lawn Mower |

| Document File Type | |

| Publisher | toro.com |

| Wikipedia's Page | Toro Company |

| Copyright | Attribution Non-commercial |

(0 votes, average: 0 out of 5)