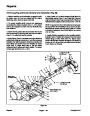

Water Valve Service (Fig. 39, 40)

The water valve controls the release of high pressure

water. The water valve is opened when a cam contacts

and moves a roller follower. The follower moves the

valve stem against spring pressure, which opens the

water valve. After discharge, the valve spring closes the

watervalve,divertingpumpflowintotheaccumulatorfor

storage. The valve stem is installed completely through

the water valve body and guided through a replaceable

bushing and two sealing assemblies.

Water Valve Disassembly

Park machine on a level surface, stop the engine, en-

gage the parking brake, open the hood and disconnect

the engine spark plug wires.

1.

WARNING: High pressure water system compo�

nents can cause personal injury if disassembled in�

correctly. Discharge water pressure at bleed valve

before attempting any water system servicing.

Open bleed valve slowly and avoid contact with

high velocity water stream.

Thewatervalveconsistsofataperedvalvestemsealing

against a captured valve seat. The valve seat is sealed

on both sides. One valve seat seal contacts the water

valve body and the other seal contacts the manifold

feeder. When the manifold feeder is installed on the wa-

ter valve, the seals are compressed, locking in and

maintaining correct alignment of the water valve and

also preventing blow by.

2.

Open High Pressure bleed valve. Remove accumula-

tor (see Accumulator Replacement). Remove manifold,

manifold feeder and manifold support as an assembly

from water valve body.

3.

Disconnect drive coupler from gear case hub adapter

(see Drive Coupling and Clutch Removal and Installa-

tion).

Any abrasives in the water will rapidly erode the valve

surfaces. The valve and valve seat can be ground and

lapped to renew their working surfaces. After grinding,

adjust the valve lift by measuring the lift and adjusting

the shim stack thickness. The shim stack is located be-

tween the water valve body and gear case flange.

4.

Drain oil from gearcase. Disconnect hydraulic lines

from gearcase. Remove four (4) capscrews securing

gear case to water valve and carefully pull gear case off

of gear box pilot on water valve.

If the high pressure seal leaks for extended periods of

time, water may be forced past the oil seal and into the

gearbox.Ifthegearboxoillooksmilkyorbrown,flushthe

system immediately, replacing oil, filter, and fluids in hy-

drostatic transmission and wheel motor.

5.

Disconnect valve seal drain tube by unscrewing small

fitting at pump inlet. Remove two (2) locknuts from studs

securing water valve to frame. Remove four (4) caps-

crews connecting water valve to water pump head. Re-

move water valve and put it on a clean work bench.

The water valve assembly is similar to the pump head.

It uses the same ceramic sleeve and seals. Since the

water valve is the junction point for all high pressure liq-

uid movement and is fairly difficult to access, complete

rebuilding is recommended when this assembly is re-

moved.

6.

Compressor (TOR4008) and into threaded holes of wa-

ter valve.

InstallvalvespringtoolstudsthroughtheValveSpring

7.

Tighten nuts to compress tool until retaining ring

(Item14) can be removed from valve spool. Remove re-

taining ring, then carefully loosen nuts on special tool re-

leasing valve spring compression.

Seal Replacement

There are two major seals in the water valve that will re-

quire regular maintenance or replacement. One seal

keeps high pressure water in the high pressure water

system and the other seal keeps the gear case oil within

the gear case.

8.

Remove spring retainer (Item 15) and spring (Item16)

from water valve stem. Remove screws (Item13) from

gear case pilot. Remove gear case pilot (Item18) from

water valve.

9.

and use a deep wall socket to loosen jam nut (Item 22)

on valve spool.

Use a wrench to keep spool valve (Item1) stationary

The high pressure water seal is identical to the pump

head displacement rod seal. The major difference is the

different brass insert.

10.

23),

Valve seat (Item 2) will come out with the valve.

Remove jam nut (Item 22) and large washer (Item

then gently push valve spool through valve body.

If the oil seal leaks, oil will leak down and through the

gear case shims. If low pressure water seal fails water

will leak out between shims. If low pressure water seal

and oil seal fail water will leak into the gear case.

Hydroject 3010

Repairs

Page 6 – 29

Rev. B

| Categories | Lawn Mower Manual, Sprinkler and Irrigation Manuals, Toro Sprinkler and Irrigation Manuals |

|---|---|

| Tags | Toro Hydroject 3010 |

| Download File |

|

| Document Type | Service Manual |

| Language | English |

| Product Brand | Toro. Customer Service Representatives are available by phone:

Monday - Friday 7:30 a.m. to 9:00 p.m. (CDT) - Saturday 8:00 a.m. to 8:00 p.m. (CDT) - Sunday 10:00 a.m. to 8:00 p.m. (CDT)

Canada 1-888-225-4886 USA 1-888-384-9939, Lawn Mower |

| Document File Type | |

| Publisher | toro.com |

| Wikipedia's Page | Toro Company |

| Copyright | Attribution Non-commercial |

(0 votes, average: 0 out of 5)