6.

Install Flow Meter (TOR4006) between water supply

hose and hose adapter. Connect hose adapter to quick

connector on side of machine.

7.

Turnon water supply. Open high pressurebleedvalve

until all air is out of the system. Close high pressure

bleed valve for pump testing. NOTE: Air in system will

cause improper test readings.

8.

9.

Disconnect hose from relief valve fitting.

THIS IS A TWO (2) PERSON OPERATION. Start

engine and operate at full speed. WEAR SAFETY

GLASSES! Have one person press and HOLD engage

button while other person stands to side of machine and

observes pressure gauge and flow meter readings.

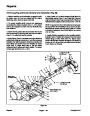

Figure 21

1.

Water supply quick connector

PRESSURE should be 5000± 300 PSI and

FLOW more than 3.4 GPM.

If pressure is too high, replace relief valve.

If pressure AND flow is low, disconnect small tube

running from bottom side of valve housing to water

pump inlet by backing out small 1/16" NPT fitting

(Fig. 39, Item 31). Plug open port with a 1/16" NPT

plug. Do this test procedure again beginning with

step 1. If pressure AND flow is still low, rebuild pump.

After rebuilding pump, do this test procedure again

beginning with step 1, to verify that valve is sealing

properly in closed position. A large quantity of water

exiting valve side of tube indicates a leaking valve

ceramic sleeve or seal. Reconnect small tube.

Figure 22

1

. Flow meter/pressure gauge (TOR4006)

If pressure is low, but flow is OK, make sure cam is

not on roller follower, keeping valve in open position.

If water is exiting outlet fitting on relief valve, replace

reliefvalve.Ifwaterisnotexitingoutletfittingonrelief

valve, rebuild water valve. After replacing relief valve

or rebuilding water valve, do this test procedure

again, beginning with step 1, to verify that pump has

adequate flow at specified operating pressure.

2

If pressure is OK, but flow is low, rebuild pump.

10.

11.

Perform Test No. 3: Water Valve Lift.

Do steps 2 - 4 and 6 - 8 of this pressure and flow test

again, with valve clutch connected to wire harness.

Figure 23

Pressure gauge needle will go rapidly to the relief

setting (5000 ± 300 PSI) for 3 to 4 seconds, then

begin to fluctuate rapidly when the unit begins aerat-

ing. Note the highest pressure. If highest pressure is

1.

Relief valve

2. Hose

4000

to 4500 PSI, plan to rebuild the valve. If pres-

sure is less than 4000 PSI, rebuild the valve.

12.

After testing is completed, open high pressure bleed

valve, then remove water system pressure gauge.

Reinstall plug in open port of water valve housing.

Connect relief valve hose. Remove flow meter.

Testing

Page 6 - 16

HydroJect 3010

Rev. A

| Categories | Lawn Mower Manual, Sprinkler and Irrigation Manuals, Toro Sprinkler and Irrigation Manuals |

|---|---|

| Tags | Toro Hydroject 3010 |

| Download File |

|

| Document Type | Service Manual |

| Language | English |

| Product Brand | Toro. Customer Service Representatives are available by phone:

Monday - Friday 7:30 a.m. to 9:00 p.m. (CDT) - Saturday 8:00 a.m. to 8:00 p.m. (CDT) - Sunday 10:00 a.m. to 8:00 p.m. (CDT)

Canada 1-888-225-4886 USA 1-888-384-9939, Lawn Mower |

| Document File Type | |

| Publisher | toro.com |

| Wikipedia's Page | Toro Company |

| Copyright | Attribution Non-commercial |

(0 votes, average: 0 out of 5)