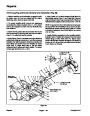

Water Pump Head Service (Fig. 36)

The three major wear components in the high pressure

pump that require maintenance include: the check val-

ves, plunger sleeves, and plunger seals. These com-

ponents will require maintenance after approx. 500

pump operating hours (approx 750 engine hours).

Pump Head Removal

1. Remove pump from machine (see Water Pump

Removal and Installation).

2.

Remove eight (8) nuts (Item 17). Carefully move

pump head (Item 11) away from pump crankcase. Turn

pump crankcase to help in removal of pump head.

WARNING

Check Valve Replacement (replace as a set)

High pressure water system components can

cause personal injury if disassembled incor�

rectly. Discharge water pressure at bleed

valve before attempting any water system

servicing. Open bleed valve slowly and avoid

contact with high velocity water stream.

1.

Remove the six caps (Item 7) and pull out check valve

assemblies.

2.

remaining seals (Item 10) stuck in the pump head.

Discard old check valves (Item 9) and remove any

NOTE: Because of high torque requirements for check

valve caps and difficulty of correctly installing check

valves in horizontal position, it is recommended that the

pump head be removed from the crankcase when ser-

vicing.

3. Insert new seals (Item 10) and check valves (Item 9).

4. Install new seals (Item 8) in check valve caps. Apply

Loctite 242 or equivalent to threads, install caps and

tighten to a torque of 205 - 235 ft-lbs.

NOTE: Whenever a pump is removed from the machine

for preventative maintenance or servicing, replace com-

ponents in complete groups rather than individually.

Complete servicing will increase the service interval

between repairs.

PLUNGER SEAL REMOVAL - Step 1:

Fill outlet port of pump head with water and

use two capscrews, to temporarily install

7

1

2

3

Pump Seal Outlet Cover (TOR4014) onto

the outlet port of the pump head.

8

13

12

4

9

11

5

10

6

16

15

14

PLUNGER SEAL REMOVAL - Step 2:

Torque to 25 - 33 ft-lb.

(Eight locations)

Fill the three (3) plunger openings with water.

Insert Pump Seal Extraction Tool (TOR4013) into

each water filled cavity. Quickly, strike the

extraction tool with a heavy lead mallet. Seal

assembly and brass retainer should move about

18

1

/4 in. out of the cylinder head. If seal does not

10

move, add more water and try again. If the seal

does not move after a few attempts, try using

heavy oil or grease instead of water.

17

9

Use Loctite 242 or equivalent

Torque to 205 - 235 ft-lb.

(Six locations)

8

7

Figure 36

Repairs

Page 6 - 24

HydroJect 3010

| Categories | Lawn Mower Manual, Sprinkler and Irrigation Manuals, Toro Sprinkler and Irrigation Manuals |

|---|---|

| Tags | Toro Hydroject 3010 |

| Download File |

|

| Document Type | Service Manual |

| Language | English |

| Product Brand | Toro. Customer Service Representatives are available by phone:

Monday - Friday 7:30 a.m. to 9:00 p.m. (CDT) - Saturday 8:00 a.m. to 8:00 p.m. (CDT) - Sunday 10:00 a.m. to 8:00 p.m. (CDT)

Canada 1-888-225-4886 USA 1-888-384-9939, Lawn Mower |

| Document File Type | |

| Publisher | toro.com |

| Wikipedia's Page | Toro Company |

| Copyright | Attribution Non-commercial |

(0 votes, average: 0 out of 5)