14.

from housing.

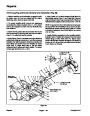

Remove pump shaft (Item 19) and bearing assembly

3. Install displacement control shaft (Item 12) into hous-

ing.

15.

washer, if used). Press shaft out of bearing.

Remove outer bearing retaining ring (Item 21) (and

4. If block spring retaining ring (Item 10) was removed

from pump shaft, install a new retaining ring at this time.

16.

(Item 10) requires replacement, remove it from pump

shaft.

If pump block retaining spring retaining ring

5. Install inner bearing retaining ring (Item 20) onto

shaft. Press bearing (Item 21) onto shaft, install washer

(if used) and new outer bearing retaining ring. Be careful

not to stretch or deform retaining rings.

17.

Remove displacement control shaft from housing.

IMPORTANT: Be careful not to damage shaft sealing

surface.

18.

Pry displacement control shaft seal out of housing.

Care must be taken so as not to damage housing bore.

If displacement control shaft journal bearing re

6.

Install pump shaft and bearing assembly intohousing.

19.

quires replacement, press it out of housing.

7. Install bearing spacer washer (Item 22).

Inspection and Replacement of Pump Parts

8. Wrap shaft with thin plastic or use a seal protector to

prevent damage to seal during installation. Lubricate

new pump shaft seal (Item 23) with petroleum jelly.

After disassembly, thoroughly clean all parts in a suit

able solvent. Replace all o-rings, gaskets and seals.

9.

Slide seal over shaft and press it into housing bore.

Inspect all parts for damage, nicks or unusual wear

patterns. Replace all parts having unusual or excessive

wear or discoloration.

Be careful not to damage the seal.

10. Install retaining ring (Item 24).

Inspect seal surfaces, bearing surfaces and shaft spli

nes. Polish sealing areas on shafts if necessary. Re

place any worn or damaged parts.

11. Install swashplate cradle bearings (Item 14) into

housing, making sure they are located on cast-in pins

in housing.

The pump shaft bushing (Item 5) is pressed into end cap

and is usually not removed.

12. Install slot guide block (Item 13) onto displacement

control shaft.

The running surfaces of cylinder blocks MUST be flat

and free from scratches. If scratches or wear are found

on running surfaces of cylinder blocks or end cap, polish

or replace the parts. When polishing these surfaces, up

to 0.0004 in. may be removed. If this is not sufficient to

obtain a flat surface, free of scratches, the part should

be replaced.

13. Install thrust plate (Item 11) into swashplate

(Item 25). Slot on swashplate must engage guide block

(Item 13) on displacement control shaft (Item 12). Use

a tool such as a screwdriver or magnet to hold guide

block in position while installing swashplate.

14. Hold swashplate in position and use a dial indicator

or depth gauge to measure side play of displacement

control shaft. Using a suitable sleeve, press control

shaft bearing into housing until control shaft end play is

between 0.020 and 0.060 in.

Assembly of Hydraulic Pump

1.

Clean and lightly oil parts before assembly. Tighten

all threaded parts to recommended torque value.

15.

Install thrust washer (Item 9) and cylinder block

IMPORTANT: Most parts have critical, high toler�

ance surfaces. Use caution to prevent damage to

these surfaces during assembly. Protect exposed

surfaces, openings and ports from damage and

foreign material.

spring (Item 8) onto pump shaft.

16. Install springs (Item 29), piston washers (Item 28)

and pistons (Item 27) into cylinder block kits. The pis

tons must move freely in their bores.

2.

If displacement control shaft bearing (Item 17) has

17. With pump swashplate in “neutral” (0 angle) position

and pump housing laying on its side, install pump cylin

der block kit onto pump shaft in housing.

been removed, press a new bearing into housing using

a suitable press pin. Surface of bearing should be flush

with inside surface of housing.

NOTE: The position of the bearing in the housing deter

mines control shaft end play. Do not press bearing

deeper into housing at this time.

Repairs

Page 4 - 20

Hydroject 3010

| Categories | Lawn Mower Manual, Sprinkler and Irrigation Manuals, Toro Sprinkler and Irrigation Manuals |

|---|---|

| Tags | Toro Hydroject 3010 |

| Download File |

|

| Document Type | Service Manual |

| Language | English |

| Product Brand | Toro. Customer Service Representatives are available by phone:

Monday - Friday 7:30 a.m. to 9:00 p.m. (CDT) - Saturday 8:00 a.m. to 8:00 p.m. (CDT) - Sunday 10:00 a.m. to 8:00 p.m. (CDT)

Canada 1-888-225-4886 USA 1-888-384-9939, Lawn Mower |

| Document File Type | |

| Publisher | toro.com |

| Wikipedia's Page | Toro Company |

| Copyright | Attribution Non-commercial |

(0 votes, average: 0 out of 5)