5.

Remove test cap from manifold feeder and install

two steps - for example if 0.023 is indicated, add 0.02

shim (four 0.005 shims) first, then repeat procedure.

Valve Lift Indicator (TOR4007) into this opening. Make

sure dial indicator contacts top of water valve, then zero

out dial indicator.

IMPORTANT: Clearances greater than 0.002 in. will

cause high contact stresses and rapid cam wear.

6.

Rotate coupling, moving cam toward cam follower.

Continue to rotateuntil cam follower is on lead-in portion

of cam, approximately one inch (slightly less than 1/2

turn of coupler) from cam lobe. If dial indicator shows

no lifting of valve, loosen four (4) capscrews holding

gear case to valve body. Remove one shim from both

front and rear, then tighten capscrews. Repeat this

procedure until some opening of valve occurs on lead-in

portion to make sure cam follower touches cam.

9. Check proper function of cam by again zeroing dial

indicator with cam away from cam follower. Rotate

coupling, movingcamtowardcamfollower and continue

to rotate until cam follower is on lead-in portion of cam,

approximately one inch from cam lobe. There should be

no movement of dial indicator on lead-in portion of cam.

Continue to rotate over cam lobe. Lift should measure

0.10

+0.002/–0.004 in. (with new cam). Continue to rotate

on lead-out portion. The dial indicator should read zero

7.

Zero dial indicator again with cam follower completely

for entire lead-out portion.

off the cam. Rotate coupling, moving cam toward cam

follower and continue to rotate until cam follower is on

lead-in portionof cam, approximately oneinch from cam

lobe. Record amount of valve lift.

IMPORTANT: Make sure shims on both front and

rear side are the same thickness. Using different

thicknesses can cause gear case damage.

8.

Add shims, equal to or greater by 0.002 inch, to

amount measured. For example, if 0.015 is measured

while follower is on lead-in portion of cam, add a 0.015

shim. If 0.009 is measured, add 0.010 shim (two 0.005

shims) and retighten capscrews.

1

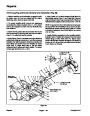

Figure 28

NOTE: If more than a multiple of 0.005 shims are

required, it is recommended that procedure be done in

1.

Valve lift indicator (TOR4007)

Water (4000 - 5000 PSI

operating pressure)

Gear case

Water valve

housing

Shims

Cam lobe

Cam follower

(on lead-in portion of cam)

Cam

Shims

Figure 29

Page 6 - 19

HydroJect 3010

Adjustments

| Categories | Lawn Mower Manual, Sprinkler and Irrigation Manuals, Toro Sprinkler and Irrigation Manuals |

|---|---|

| Tags | Toro Hydroject 3010 |

| Download File |

|

| Document Type | Service Manual |

| Language | English |

| Product Brand | Toro. Customer Service Representatives are available by phone:

Monday - Friday 7:30 a.m. to 9:00 p.m. (CDT) - Saturday 8:00 a.m. to 8:00 p.m. (CDT) - Sunday 10:00 a.m. to 8:00 p.m. (CDT)

Canada 1-888-225-4886 USA 1-888-384-9939, Lawn Mower |

| Document File Type | |

| Publisher | toro.com |

| Wikipedia's Page | Toro Company |

| Copyright | Attribution Non-commercial |

(0 votes, average: 0 out of 5)