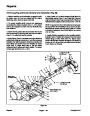

Controller (Fig. 11)

The controller senses the condition of various switches,

such as the transport switch and aerate start switch and

directs power output to allow certain machine functions,

such as aerate engage, disengage and timing of those

functions.

Because of the solid state circuitry built into the control

ler, there is no method to test it directly. The controller

may be damaged if an attempt is made to test it with an

electrical test device, such as a volt-ohm meter.

1

2

3

IMPORTANT: Before welding on the machine, dis�

connect both battery cables from the battery, dis�

connect both wire harness plugs fromtheelectronic

control unit and disconnect the terminal connector

from the alternator to prevent damage to the electri�

cal system.

Figure 11

1. Red light

2. Yellow light

3. Green light

Lights (LED’s) on the controller indicate the condition of

the interlock switches. The LED’s, in conjunction with

the following tests for interlock switches, should be used

to help isolate a problem in an interlock switch, wiring

or the controller (see Wiring Schematics and Diagrams).

Traction Switch 1 and 2 (Fig. 12)

Traction switch 1 is normally open (N.O.) and is closed

when traction bail is neutral. Traction switch 2 is nor

mally closed (N.C.) and is open when the traction bail is

in neutral.

3

IMPORTANT: Traction switch 1 and 2 have three (3)

terminals. Traction switch 1 must have the wires

connected to the “COMMON” and “N.O.” terminals.

The Traction switch 2 must have the wires con�

nected to the “COMMON” and “N.C.” terminals. If

the wires are not connected to the correct terminals,

on each switch the safety interlock circuit will not

function properly.

1

2

Test the switch by disconnecting the wires from the

switch terminals and connecting a continuity tester

across the two terminals that had wires connected to

them. With the engine turned off, slowly push the trac

tion bail in a forward and reverse direction while watch

ing the continuity tester. There should be indicationsthat

the switch is opening and closing. Allow the traction bail

to return to neutral. There should be continuity across

the terminals of traction switch 1 and no continuity

across the terminals of the traction switch 2. (See Trac

tion Switch 1 and 2 Replacement and Adjustment in the

Repairs section of this chapter for replacement and

adjustment procedures.)

Figure 12

1. Traction switch 1 –– N.O. (gray & black wires)

2. Traction switch 2 –– N.C. (orange & yellow wires)

3. Switch tab

Testing

Page 5 - 18

Hydroject 3010

| Categories | Lawn Mower Manual, Sprinkler and Irrigation Manuals, Toro Sprinkler and Irrigation Manuals |

|---|---|

| Tags | Toro Hydroject 3010 |

| Download File |

|

| Document Type | Service Manual |

| Language | English |

| Product Brand | Toro. Customer Service Representatives are available by phone:

Monday - Friday 7:30 a.m. to 9:00 p.m. (CDT) - Saturday 8:00 a.m. to 8:00 p.m. (CDT) - Sunday 10:00 a.m. to 8:00 p.m. (CDT)

Canada 1-888-225-4886 USA 1-888-384-9939, Lawn Mower |

| Document File Type | |

| Publisher | toro.com |

| Wikipedia's Page | Toro Company |

| Copyright | Attribution Non-commercial |

(0 votes, average: 0 out of 5)