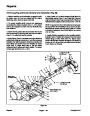

Charge Pump Service (Fig. 24)

1.

(2)

Use a 5 mm internal hex wrench to remove the two

screws holding charge pump cover to pump end cap.

Top of pump when

installed in machine

NOTE: Charge pump rotation is determined by orienta

tion of charge pump cover on pump end cap. Cast boss

on charge pump cover indicates orientation. Note orien

tation of cast boss before removing charge pump cover.

2.

3.

4.

5.

end cap for abnormal wear, damage or foreign material.

Inspect charge relief valve seat in end cap for damage

or foreign material.

Remove charge pump cover and O-ring.

Remove charge pump gerotor assembly.

Remove charge relief valve spring and ball.

Inspect gerotor assembly, charge pump cover and

2

3

5

4

1

Torque to

84 to 120 in-lb.

Figure 24

6.

of petroleum jelly to inside diameter, outside diameter

and slide faces of gerotor assembly.

Before installing charge pump, apply a small amount

1. Charge pump cover

2. O-ring

3. Gerotor assembly

4. Charge relief ball

5. Charge relief spring

7.

8.

9.

Install charge relief ball and spring.

Install charge pump gerotor assembly.

Install charge pump cover and O-ring. Make sure

charge relief spring enters recess in cover.

10.

Install charge pump cover screws and tighten to a

torque of 84 to 120 in-lb.

Major Pump Repair (Fig. 25, 26)

The procedures on the following pages are for complete

disassembly and reassembly of the pump.

During assembly of the pump, all surfaces which have

relative motion between two parts should be coated with

a film of clean hydraulic oil. This will assure that these

surfaces will be lubricated during start-up.

Cleanliness is a primary means of assuring satisfactory

transmission life, on either new or repair units. Cleaning

parts by using a clean solvent wash and air drying is

usually adequate. As with any precision equipment, all

parts must be kept free of foreign materials and chemi

cals. Protect all sealing surfaces and open cavities from

damage and foreign material.

It is recommended that all gaskets, o-rings and seals be

replaced. Lightly lubricate all o-rings with clean petro

leum jelly before assembly. All gasket sealing surfaces

must be cleaned before installing new gaskets.

Repairs

Page 4 - 18

Hydroject 3010

| Categories | Lawn Mower Manual, Sprinkler and Irrigation Manuals, Toro Sprinkler and Irrigation Manuals |

|---|---|

| Tags | Toro Hydroject 3010 |

| Download File |

|

| Document Type | Service Manual |

| Language | English |

| Product Brand | Toro. Customer Service Representatives are available by phone:

Monday - Friday 7:30 a.m. to 9:00 p.m. (CDT) - Saturday 8:00 a.m. to 8:00 p.m. (CDT) - Sunday 10:00 a.m. to 8:00 p.m. (CDT)

Canada 1-888-225-4886 USA 1-888-384-9939, Lawn Mower |

| Document File Type | |

| Publisher | toro.com |

| Wikipedia's Page | Toro Company |

| Copyright | Attribution Non-commercial |

(0 votes, average: 0 out of 5)