8.

holder to inner housing.

Remove four (4) cap screws that secure bearing

5. Install rotor shaft assembly into inner housing. Make

sure to align marker line made during disassembly and

thatbearingisfullyseatedinhousingbearingbore.Also,

make sure that bearing holder slides fully into inner

housing and that rotor shaft rotates freely.

9.

inner housing.

Slide rotor shaft and bearing holder assembly from

10.Remove

front bearing cap to bearing holder. Remove bearing

holder from rotor shaft assembly.

four (4) flange head screws that secure

6.

Install four (4) cap screws to secure bearing holder

to inner housing. Tightenscrews in three (3) equalsteps

and in a crossing pattern. Final torque on screws should

be from 180 to 210 in--lb (21 to 23 N--m).

11.

Remove bearings from rotor shaft:

A. Press bearings from shaft.

7.

tion in this section).

Install rotor assembly (see Rotor Assembly Installa-

B. Remove front bearing cap and inner retaining

rings from shaft if necessary.

8.

Installation in this section).

Install blower drive shaft (see Blower Drive Shaft

12.Inspect

holder and inner housing for wear or damage. Replace

parts as necessary.

rotor shaft and bearing bores of bearing

9.

Install top grill to machine (Fig. 8).

nozzle pulley and nozzle to rear of outer hous-

10.Install

ing (see Nozzle Assembly Installation) in this section).

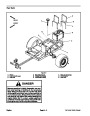

Installation (Fig. 7)

11.

Connect negative battery cable to negative battery

1.

Install bearings onto rotor shaft:

terminal. Tighten nut that secures battery cable from 10

to 15 ft--lb(14 to 20 N--m).Make sure that battery cover

is secured.

A. Install inner retaining rings into shaft groove if

they were removed.

B. Make sure that front bearing cap (item 6) is

placed on rotor shaft between bearing locations.

4

1

1

3

2

C. Install bearings onto shaft by pressing on inner

race. Make sure that bearings are seated against in-

ner retaining ring.

2

1

IMPORTANT: To prevent the bearings from rotating

in the inner housing or bearing holder, Loctite Prim-

er N (or equivalent) and Loctite Product 641 (or

equivalent) must be used during assembly.

1

5

3

2.

Clean bearing bores of bearing holder and inner

housing with brake parts cleaner or similar non--oily

cleaner. After cleaner dries completely, apply Loctite

Primer N (or equivalent) to bearing bores. Allow Primer

to dry completely.

3.

ply Loctite Product 641 (or equivalent) to OD of both

bearings.

Thoroughly clean OD of bearings on rotor shaft. Ap-

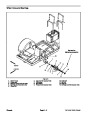

Figure 8

1.

2.

3.

Screw

Washer

Flange nut

4.

5.

Top grill

Side grill

4.

Slide bearing holder onto bearing on rotor shaft.

Position front bearing cap (item 6) to bearing holder and

secure with four (4) flange head screws.

NOTE: Later production bearing holder (item 2) has a

groove that locates onto tab on inner housing (item 8).

If equipped, make sure that these items align during as-

sembly.

ProForce Debris Blower

Page 5 -- 9 Rev. A

Blower Assembly

| Categories | Lawn Mower Manual, Sprinkler and Irrigation Manuals, Toro Sprinkler and Irrigation Manuals |

|---|---|

| Download File |

|

| Document Type | Catalog |

| Language | English |

| Product Brand | Toro. Customer Service Representatives are available by phone:

Monday - Friday 7:30 a.m. to 9:00 p.m. (CDT) - Saturday 8:00 a.m. to 8:00 p.m. (CDT) - Sunday 10:00 a.m. to 8:00 p.m. (CDT)

Canada 1-888-225-4886 USA 1-888-384-9939, Lawn Mower |

| Document File Type | |

| Publisher | toro.com |

| Wikipedia's Page | Toro Company |

| Copyright | Attribution Non-commercial |

(0 votes, average: 0 out of 5)