2.

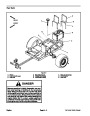

Place inner housing assembly with the rotor shaft

D. Torque screws (item 12) that secure stator vanes

to outer housing from 10 to 20 in--lb (1.2 to 2.2

N--m). Use a crossing pattern while torquing the

screws.

pointing upwards onto two (2) wood planks (2” x 4” or

equivalent). Carefully lower outer housing around inner

housing assembly. Then, place 9/16” (14.3 mm) thick

support between planks and outer housing (Fig. 15).

This process should allow alignment of mounting holes

in inner housing flanges to outer housing.

CAUTION

NOTE: When assembling inner and outer housings, do

not fully tighten any screws until all screws are installed

to inner housing flanges and stator vanes. Also, use

hand tools rather than air impact tools during assembly.

To prevent personal injury, make sure that outer

housing assembly is properly supported as it is

positioned to machine. Assembly weighs

approximately 70 pounds (31.8 kg).

3.

Make sure that holes in inner housing flanges align

with outer housing holes. Install and finger tighten eight

flange head screws (item 15) into threads of inner

housing flanges. Do not fully tighten screws at this time.

6.

Positionouterhousingassemblytomachine.Secure

outer housing to fan housing mounts with cap screws

and flange nuts.

(8)

4.

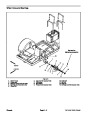

Install stator vanes to inner and outer housing:

7.

Install rotor assembly (see Rotor Assembly Installa-

A. Positionavanebetweeninnerandouterhousing.

Make sure that rounded end of vane is orientated to-

ward rotor shaft (Fig. 16).

tion in this section).

8.

Install blower drive shaft (see Blower Drive Shaft

Installation in this section).

B. Tilt vane and engage vane lugs to inner housing

holes.

9.

Install top grill to machine (Fig. 14).

nozzle pulley and nozzle to rear of outer hous-

10.Install

ing (see Nozzle Assembly Installation in this section).

C. While keeping vane lugs in inner housing holes,

rotate vane to align threaded hole of vane with outer

housing hole.

11.

Connect negative battery cable to negative battery

terminal. Tighten nut that secures battery cable from 10

to 15 ft--lb(14 to 20 N--m).Make sure that battery cover

is secured.

D. Install and finger tighten flange head screw (item

12)

into threads of vane. Do not fully tighten screw at

this time.

E. Repeat process for all twenty--four (24) vanes.

ROUNDED

END

5.

Tighten fasteners in the following order to secure as-

sembly:

2

A. Use nutdriver to hand tighten the eight (8) flange

3

head screws (item 15) that secure inner housing

flanges to outer housing. Use a crossing pattern

while tightening the screws.

B. Use nutdriver to hand tighten the flange head

screws (item 12) that secure the twenty--four (24)

statorvanestoouterhousing.Useacrossingpattern

while tightening the screws.

INTAKE

END

1

C. Torque flange head screws (item 15) that secure

inner housing flanges to outer housing from 90 to

100

in--lb(10.2to11.2N--m).Useacrossingpattern

4

while torquing the screws.

IMPORTANT: DO NOT overtighten screws that

secure stator vanes to outer housing. If screws

are overtightened, threads in vanes could be

damaged.

DISCHARGE

5

END

Figure 16

1.

2.

3.

Outer housing

Inner housing assembly

Stator vane (24 used)

4.

5.

Flange head screw

Flange head screw

Blower Assembly

Page 5 -- 14

ProForce Debris Blower

| Categories | Lawn Mower Manual, Sprinkler and Irrigation Manuals, Toro Sprinkler and Irrigation Manuals |

|---|---|

| Download File |

|

| Document Type | Catalog |

| Language | English |

| Product Brand | Toro. Customer Service Representatives are available by phone:

Monday - Friday 7:30 a.m. to 9:00 p.m. (CDT) - Saturday 8:00 a.m. to 8:00 p.m. (CDT) - Sunday 10:00 a.m. to 8:00 p.m. (CDT)

Canada 1-888-225-4886 USA 1-888-384-9939, Lawn Mower |

| Document File Type | |

| Publisher | toro.com |

| Wikipedia's Page | Toro Company |

| Copyright | Attribution Non-commercial |

(0 votes, average: 0 out of 5)