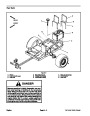

Removal (Fig. 3)

Have ProCore Processor attached to tow vehicle

C. Pack both bearing cones with grease. Install

greased inner bearing cone into the cup on inboard

side of the wheel hub.

1.

and park machines on a level surface. Engage vehicle

parking brake, stop engine and remove key from the

ignition switch. Make sure that Processor engine is off.

Chock wheels to prevent movement of either machine.

IMPORTANT: The grease seal must be pressed

in so it is flush with the end of the hub. The lip of

the seal must face the inner bearing.

2.

Topreventunexpectedbloweroperation,disconnect

D. Lubricatetheinsideofnewgreasesealandpress

it into the wheel hub.

the negative battery cablefrom thebattery terminal (see

Battery Service in the Service and Repairs section of

Chapter 4 -- Electrical System). Position disconnected

negative cable away from the negative battery terminal.

3.

Install the wheel hub onto the axle spindle taking

care to not damage grease seal in hub.

4.

jam nut onto spindle shaft.

Install greased outer bearing cone, tab washer and

3.

jack stands (see Operator’s Manual and Jacking In-

structions in Chapter 1 -- Safety).

Jack or hoist blower from ground and support with

5.

While rotating the wheel hub by hand, torque the jam

nut from 75 to 180 in-lb (8.5 to 20.3 N--m) to seat bear-

ings.Loosen nutuntilitisawayfromtabwasher andhub

has end play. Finally, while rotating hub, tighten jam nut

from 15 to 20 in--lbs (1.7 to 2.3 N--m).

4.

this section).

Remove wheel assembly (see Wheel Removal in

5.

6.

7.

Carefully pry dust cap from wheel hub.

Straighten cotter pin and remove from axle spindle.

Removenutretainer,jamnutandtabwasherthatse-

6. Install nut retainer and cotter pin to secure jam nut.

Install dust cap to hub.

curewheelhubtospindle.Slidewheelhubwithbearings

from spindle.

WARNING

8.

Disassemble wheel hub:

Failure to maintain proper lug nut torque could

resultinfailureorloss ofwheelandmayresultin

personal injury.

A. Remove grease seal from the wheel hub taking

care to not damage the hub bore. Discard seal.

B. Remove bearing cones from both sides of wheel

hub. Clean bearings in solvent. Clean inside of hub.

7. Installwheelassembly(seeWheelInstallation inthis

section).

C. If necessary, remove bearing cups from hub.

8. Carefully lower machine to ground. Make sure to

properly torque wheel lug nuts from 60 to 65 ft--lb (81

to 88 N--m).

D. Inspectwheelbearings.Checkthebearingcones

and bearing cups for wear, pitting or other damage.

Replace worn or damaged parts.

9. Connect negative battery cable to negative battery

terminal. Tighten nut that secures battery cable from 10

to 15 ft--lb(14 to 20 N--m).Make sure that battery cover

is secured.

9.

Inspectaxleforwearordamage.Replaceaxleifnec-

essary.

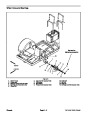

Installation (Fig. 3)

1.

Thoroughly clean all wheel hub components before

assembly.

2.

Assemble wheel hub:

A. If bearing cups were removed from the wheel

hub, press inner and outer cups into the hub until

they seat against the hub shoulder.

B. Fill hub approximately 50% full of grease.

ProForce Debris Blower

Page 6 -- 7

Chassis

| Categories | Lawn Mower Manual, Sprinkler and Irrigation Manuals, Toro Sprinkler and Irrigation Manuals |

|---|---|

| Download File |

|

| Document Type | Catalog |

| Language | English |

| Product Brand | Toro. Customer Service Representatives are available by phone:

Monday - Friday 7:30 a.m. to 9:00 p.m. (CDT) - Saturday 8:00 a.m. to 8:00 p.m. (CDT) - Sunday 10:00 a.m. to 8:00 p.m. (CDT)

Canada 1-888-225-4886 USA 1-888-384-9939, Lawn Mower |

| Document File Type | |

| Publisher | toro.com |

| Wikipedia's Page | Toro Company |

| Copyright | Attribution Non-commercial |

(0 votes, average: 0 out of 5)