Controller

The Workmancontroller is secured to therear frameun-

der the controller cover beneath the cargo box (Fig. 40).

Thecontroller usesinputsfromseveralvehicleswitches

(on/off, forward/reverse, accelerator pedal, supervisor,

charger interlock, motor temperature, accelerator po-

tentiometer) toaccurately controlvehiclespeed,vehicle

direction (forward and reverse) and regenerative brak-

ing. An internal thermal sensor prevents overheating of

the controller.

NOTE: If the controller LED and vehicle status light are

flashing,attempttoresetthecontrollerbyturningtheon/

off switch to OFF, waiting a few seconds and then turn-

ing the switch to ON. If LED and status light continue

flashing, proceed with fault code identification and nec-

essary action.

1

3

Cable connections for the controller are as follows:

Terminal B--: Negative (--) battery cable and wire

harness ground.

Terminal B+: Positive (+) cable from main contac-

tor post and wire harness fusible link (FL3).

Terminal M1: Cable to traction motor armature A2

post.

2

Terminal M2: Cable to traction motor armature A1

post.

Terminal F1: Cable to traction motor field F1 post.

Terminal F2: Cable to traction motor field F2 post.

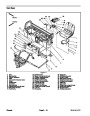

Figure 40

When installing cables to controller, torque screws at

terminals B--, B+, M1 and M2 from 85 to 90 in--lb (9.6

to 10.2 N--m) and torque screws at terminals F1 and F2

from 55 to 60 in--lb (6.2 to 6.8 N--m) (Fig. 41). Apply

Toro battery terminal protector (see Special Tools) to

controller connections after tightening terminal screws.

1.

2.

Controller

Controller LED

3.

Wire harness connector

UP

M2

If wire harness connector is removed from controller,

both harness connector and controller socket should be

filled with dielectric gel to prevent corrosion of connec-

tion terminals and potential controller damage. Apply

gel fully to both harness connector and controller sock-

et, plug harness connector into controller to distribute

gel, unplug harness connector, reapply gel to both sur-

faces and plug harness connector into controller.

M1

85

to 90 in--lb

to 10.2 N--m)

(9.6

B+

B-

F2

F1

-

A LED exists on the controller to identify normal opera-

tion or faults that will prevent the vehicle from operating

correctly. The vehicle status light on the dash panel dis-

plays the same information as the LED on the controller.

See chart below for lightpattern faultcodes identified by

the controller LED and vehicle status light.

55

(6.2 to 6.8 N--m)

to 60 in--lb

Figure 41

Light Pattern

Cause

Necessary Action

Always on (not

flashing)

System functioning correctly. None

Always off

System inoperable.

Check for low battery voltage, faulty fuse(s), loose

battery cable connections, damaged battery cables

and/or faulty main contactor.

If batteries, cables and other electrical components are

in good condition, controller replacement may be

necessary.

Electrical System

Workman MDE

Page 3 -- 26

| Categories | Lawn Mower Manual, Sprinkler and Irrigation Manuals, Toro Sprinkler and Irrigation Manuals |

|---|---|

| Download File |

|

| Document Type | Catalog |

| Language | English |

| Product Brand | Toro. Customer Service Representatives are available by phone:

Monday - Friday 7:30 a.m. to 9:00 p.m. (CDT) - Saturday 8:00 a.m. to 8:00 p.m. (CDT) - Sunday 10:00 a.m. to 8:00 p.m. (CDT)

Canada 1-888-225-4886 USA 1-888-384-9939, Lawn Mower |

| Document File Type | |

| Publisher | toro.com |

| Wikipedia's Page | Toro Company |

| Copyright | Attribution Non-commercial |

(0 votes, average: 0 out of 5)