Removal (Fig. 6)

Park machine on a level surface, stop engine, set

Installation (Fig. 6)

1.

1. Ifbrakepads wereremoved fromcaliper,installpads

(Fig. 7):

parking brake and remove key from the ignition switch.

A. If brake pads are being replaced, it will be neces-

sarytopushcaliperpistonsbackintothecaliperbore

before installing new pads.

WARNING

Beforejackingupthemachine,reviewandfollow

Jacking Instructions in Chapter 1 -- Safety.

B. Slide brake pads into caliper. Make sure that fric-

tion material on pads is toward brake rotor position.

C. Secure pads into caliper with two (2) pins. Make

sure that pins snap into caliper slots. Install anti--

rattle clip to caliper, pin and brake pads.

2.

off the ground and support machine with appropriate

jack stands.

Chock wheels not being jacked up. Jack front wheel

2.

rotor is between brake pads.

Slide brake caliper onto brake rotor. Make sure that

3.

Steering and Front Wheel Removal in the the Service

and Repairs section of Chapter 5 -- Chassis).

Remove front wheel from machine (see Lower

3.

Align caliper mounting holes with spindle. Secure

caliper with two (2) cap screws and lock washers.

4.

Clean hydraulic brake line area of brake caliper to

prevent contamination. Loosen and disconnect brake

line from caliper. Plug brake line and position it away

from caliper.

4.

5.

6.

Install brake hose to caliper.

Install front wheel assembly.

5.

Remove two (2) cap screws and lock washers that

secure the brake caliper to the spindle.

Lowermachinetoground.Torquelugnutsinacross-

ing pattern from 45 to 65 ft--lb (61 to 88 N--m).

6.

per from machine.

Slide brake caliper from brake rotor and remove cali-

7.

tion).

Bleed brakes (see Bleed Brake System in this sec-

7.

7):

If necessary, remove brake pads from caliper (Fig.

A. Remove anti--rattle clip from caliper.

CAUTION

After servicing the brakes, always check the

brakes in a wide open, level area that is free of

other persons and obstructions.

B. Remove pins from caliper by prying with a flat

blade screwdriver through loop in pins.

C. Slide brake pads from caliper. For assembly pur-

poses, note orientation of inner and outer pads as

the pads are not the same.

8.

Check brake operation.

D. Replace the brake pads if the friction material is

worn to less than 1/32” (0.8 mm).

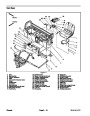

3

2

8.

If brake rotor service is necessary, see Lower Steer-

ingandFrontWheelsintheServiceandRepairssection

of Chapter 5 -- Chassis.

1

Figure 7

1.

2.

Brake pad

Pin (2 used)

3. Anti--rattle clip

Workman MDE

Page 4 -- 15

Transaxle and Brakes

| Categories | Lawn Mower Manual, Sprinkler and Irrigation Manuals, Toro Sprinkler and Irrigation Manuals |

|---|---|

| Download File |

|

| Document Type | Catalog |

| Language | English |

| Product Brand | Toro. Customer Service Representatives are available by phone:

Monday - Friday 7:30 a.m. to 9:00 p.m. (CDT) - Saturday 8:00 a.m. to 8:00 p.m. (CDT) - Sunday 10:00 a.m. to 8:00 p.m. (CDT)

Canada 1-888-225-4886 USA 1-888-384-9939, Lawn Mower |

| Document File Type | |

| Publisher | toro.com |

| Wikipedia's Page | Toro Company |

| Copyright | Attribution Non-commercial |

(0 votes, average: 0 out of 5)