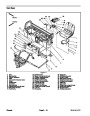

Disassembly (Fig. 2)

2. Ifsealswereremoved,pressnewsealsintohousing.

Seal lips should be facing up.

IMPORTANT:Do not reuse flange head screw with

patch lock after it has been removed.

3. Place flat washer (item 5) onto shaft of the Pitman

arm (item 19). Insert shaft into steering housing.

1.

Remove flange head screw with patch lock (item 9)

and stepped washer (item 8) from Pitman arm. Discard

flange head screw.

IMPORTANT:The position of the Pitman arm and

sectorgeariscriticalduringgearboxassembly.Ifei-

ther or both of these parts is replaced, make sure

their alignment matches the matchmark position of

the original gear and arm.

2.

Remove flange head screw with patch lock (item 13)

andflatwasher (item 12)from piniongear shaft.Discard

flange head screw.

4.

Pitman arm shaft.

Position sector gear (item 4) onto the spline of the

3.

Remove three (3) hex washer head screws (item 2)

securing the housing cover and gasket to the steering

housing. Remove cover and gasket from the housing.

Replace gasket if damaged.

IMPORTANT:Make sure sector gear is centered to

the pinion gear.

4.

free of damage that prevents them of free movement.

Inspect gears. Sector and pinion gear teeth must be

5. Insert pinion gear (item 17) into the small bearing in

the steering housing.

5.

Remove pinion gear (item 17) from the housing.

6. Fill steering housing with number 2 general purpose

grease. Make sure all gear teeth on the sector and pin-

ion gears are covered with grease.

IMPORTANT:Matchmark pitman arm shaft and sec-

torgear.Theirpositioniscriticalduringreassembly.

7.

housing. Secure cover to housing with three (3) hex

washer head screws (item 2). Torque screws from 90 to

110

Place gasket and steering housing cover onto the

6.

(item 4) and steering housing and remove from the

housing.

Separate Pitman arm (item 19) from the sector gear

in--lb (10.2 to 12.4 N--m).

7.

be free of damage. Press bearings and spacer out of

housing if necessary.

Inspect bearings. Bearings must spin smoothly and

IMPORTANT:Flange head screws with patch lock

(items 9 and 13) should be replaced whenever they

are removed.

8.

Replace seals if necessary.

Inspect seals. Seals must be free of rips and tears.

8.

Secure stepped washer and flange head screw with

patchlock(item9)tothePitmanarm(item8).Makesure

topositionsteppedwasherasshowninFigure2.Torque

screw from 27 to 33 ft--lb (37 to 44 N--m).

Assembly (Fig. 2)

IMPORTANT:Always replace ball bearings as a set.

9.

Secure flat washer (item 12) and flange head screw

with patch lock (item 13) to the pinion gear shaft. Torque

screw from 175 to 225 in--lb (20 to 25 N--m).

1.

If ball bearings were removed:

A. Press new bearing into housing from the inside

first.

10.After

arm rotates freely from stop to stop without binding.

assembly is completed, make sure that pitman

B. Turn housing over. Insert spacer and press new

bearing into housing.

Workman MDE

Page 5 -- 9

Chassis

| Categories | Lawn Mower Manual, Sprinkler and Irrigation Manuals, Toro Sprinkler and Irrigation Manuals |

|---|---|

| Download File |

|

| Document Type | Catalog |

| Language | English |

| Product Brand | Toro. Customer Service Representatives are available by phone:

Monday - Friday 7:30 a.m. to 9:00 p.m. (CDT) - Saturday 8:00 a.m. to 8:00 p.m. (CDT) - Sunday 10:00 a.m. to 8:00 p.m. (CDT)

Canada 1-888-225-4886 USA 1-888-384-9939, Lawn Mower |

| Document File Type | |

| Publisher | toro.com |

| Wikipedia's Page | Toro Company |

| Copyright | Attribution Non-commercial |

(0 votes, average: 0 out of 5)