Brush Service

Check the brush springs for correct alignment on the

back of the brush. A brush spring that does not apply

equal pressure on the center of the brush will cause the

brushtowearunevenly.Checkforcorrectclearanceand

freedom of brush movement in the holder.

3. It is also recommended that the field be coated with

PD George 1000--70 or RanBar B--535--5S varnish for

proper insulation protection. Both recommended var-

nishes are Class H water--soluble varnishes. A similar

air--dry varnish may also be used providing it has a

Class H rating.

1.

4.

be torqued from 250 to 300 in--lb (28.3 to 33.9 N--m)

(Fig. 59).

Screws securing the pole pieces to the frame should

2.

(16

even wear or show signs of overheating, such as discol-

ored brush shunts and brush springs.

Replace brushes that are worn to a length of 0.620”

mm). Also, replace brushes if they show signs of un-

3

3.

Brushes should always be replaced incomplete sets

of eight. Use identical replacement parts; do not substi-

tute brush grades as the brushes are matched to the

motor type and application to provide the best service.

Substituting brushes of the wrong grade can cause pre-

mature commutator failure and excessive brush wear.

Remove old brushes and replace with identical replace-

ment parts. Hold brush shunts in position and torque

brushscrewsfrom18to22in--lbs(2.0to2.5N--m)(Fig.

2

1

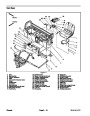

Figure 57

1.

2.

Motor housing

Puller

3.

Arbor press

59).

Make sure brushes move freely in the holders and

thatshuntsdonotinterferewithbrushspringmovement.

4.

Make sure the brush box assembly is tight on the

1

commutator end head. Replace brush box assemblies

in the commutator end head if they are physically dam-

aged or brush holders are loose on the brush plate.

5.

using the following procedure (Fig. 58):

Brush springs should be checked for proper tension

2

3

A. Place paper strip between brush face and com-

mutator. Hook spring scale as shown.

B. Pull spring scale on a line directly opposite the

line of force exerted by the brush spring. When the

paperstripbeginstomovefreely,readthespringten-

sion on the scale. Brush tension for a new brush

should be 65 ounces (1820 grams) and for a worn

brush should be 40 ounces (1120 grams).

Figure 58

3.

1.

2.

Spring scale

Brush spring

Paper

2

Frame and Field Service

1.

Motors that have been disassembled for servicing

should be given a complete inspection of the frame and

field assembly. If damage to the field coils or frame is

found, replace traction motor. Individual frame and field

components are not available.

2

1

2.

Accumulated carbon dust, grease and other foreign

material can produce a ground path from the field wind-

ing to the frame. The frame and field should be cleaned

with Safety--Kleen 105 washing solvent or equivalent.

After cleaning, the frame and field must be oven--dried

for one hour at 300oF (148o C) to remove any cleaning

Figure 59

2.

1.

Brush screw

Pole piece screw

residue.

Workman MDE

Electrical System

Page 3 -- 39

| Categories | Lawn Mower Manual, Sprinkler and Irrigation Manuals, Toro Sprinkler and Irrigation Manuals |

|---|---|

| Download File |

|

| Document Type | Catalog |

| Language | English |

| Product Brand | Toro. Customer Service Representatives are available by phone:

Monday - Friday 7:30 a.m. to 9:00 p.m. (CDT) - Saturday 8:00 a.m. to 8:00 p.m. (CDT) - Sunday 10:00 a.m. to 8:00 p.m. (CDT)

Canada 1-888-225-4886 USA 1-888-384-9939, Lawn Mower |

| Document File Type | |

| Publisher | toro.com |

| Wikipedia's Page | Toro Company |

| Copyright | Attribution Non-commercial |

(0 votes, average: 0 out of 5)