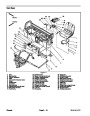

Assembly (Fig. 56)

ARMATURE

ASSEMBLY

PRESS FIXTURE

MUST PRESS

AGAINST

NOTE: After the motor has been disassembled, it is

recommended that a new commutator end head bear-

ingbeinstalled because theremoved bearing mayhave

been damaged during disassembly. Although the bear-

ing may appear and feel good, the bearing could be ”bri-

nelled” (races or balls deformed) and may exhibit noise

andvibrationproblemsorfailwithin arelatively shortpe-

riod of service. When installing new bearing, always

press against the race that is absorbing the pressure or

bearing damage may occur.

OUTER RACE

BEARING AND

RETAINING RING

INSTALLED

IN END HEAD

BEARING

PRESS FIXTURE

MUST HOLD

END HEAD

MUST BE HELD

STATIONARY

INNER RACE

STATIONARY

1.

After servicing the commutator and brushes, re--as-

Figure 61

semble the wiring in the commutator end head as origi-

nally found. Ensure the wiring does not contact metal

androtatingparts.Also,makesurethatthewiringallows

the brushes to move unrestricted in the brush holders.

1

2

2.

pressingonthebearingouterraceonly(Fig.61).Secure

bearing with retaining ring.

Press a new bearing into the commutator end head,

3

4

5

3.

field assembly and secure with four (4) bolts. Torque

Position the commutator end head to the frame and

Figure 62

4.

5.

bolts from 120 to 140 in--lb (13.6 to 15.8 N--m).

1.

2.

3.

Terminal

Lower nut

Flat washer

Insulating washer

Motor housing

4.

5.

Ensure the brushes are pushed out of the way.

While supporting the inner--race of the bearing in

commutator end head, carefully press the armature into

the end head and bearing assembly (Fig. 61).

2

6.

Position brushes in brush holders and carefully re-

1

lease the brush springs allowing the brushes to contact

the commutator. Make sure brush shunts do not inter-

fere with spring movement.

4

7.

the headband on the motor.

Repair or replace the headband if damaged. Install

3

8.

Make sure that lower nuts are properly tightened on

traction motor terminals (Fig. 62 and 63). Lower nuts on

F1andF2terminals shouldbetorquedfrom50to60in--

lb (5.7 to 6.8 N--m). Lower nuts on A1 and A2 terminals

should be torqued from 110 to 140 in--lb (12.4 to 15.8

N--m).

Figure 63

3.

4.

1.

2.

A2 terminal

F2 terminal

F1 terminal

A1 terminal

Workman MDE

Electrical System

Page 3 -- 41

| Categories | Lawn Mower Manual, Sprinkler and Irrigation Manuals, Toro Sprinkler and Irrigation Manuals |

|---|---|

| Download File |

|

| Document Type | Catalog |

| Language | English |

| Product Brand | Toro. Customer Service Representatives are available by phone:

Monday - Friday 7:30 a.m. to 9:00 p.m. (CDT) - Saturday 8:00 a.m. to 8:00 p.m. (CDT) - Sunday 10:00 a.m. to 8:00 p.m. (CDT)

Canada 1-888-225-4886 USA 1-888-384-9939, Lawn Mower |

| Document File Type | |

| Publisher | toro.com |

| Wikipedia's Page | Toro Company |

| Copyright | Attribution Non-commercial |

(0 votes, average: 0 out of 5)