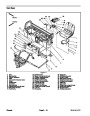

Inspection (Fig. 4)

Assembly (Fig. 4)

1.

Inspect brake drums.

IMPORTANT:Brake shoe lining surfaces must be

free of grease, oil and other foreign matter.

IMPORTANT:Brake drum machining is not re-

commended. Replace brake drums as a set to

maintain equal braking forces.

1. Apply a light film of lubricant to the following:

A. Ledges on which the brake shoes rest.

B. Pin surfaces on adjuster levers.

A. Clean drums with denatured alcohol. Check

braking surface diameter in at least three places. If

the diameter exceeds 6.320” (160.5 mm), replace

both brake drums.

C. Anchor block surface that contacts shoe webs.

D. Both surfaces of belleville washers that are posi-

tioned between adjuster levers and backing plate.

B. Replacedrumsthatarecracked,deeplygrooved,

tapered, significantly out--of--round, scored, heat

spotted or excessively rusted.

2.

If removed, position lubricated belleville washer be-

tween lever adjuster and backing plate. Secure adjuster

to backing plate with washer and bolt. Torque bolt from

C. Minor scoring can be removed with sandpaper.

Inspect brake shoe linings.

110

to 120 in--lb (12.4 to 13.6 N--m).

2.

3.

with two (2) washer head screws. Torque screws from

110

If removed, secure wheel cylinder to backing plate

IMPORTANT:Replace brake shoes as a set (all

four shoes) to maintain equal braking forces.

to 120 in--lb (12.4 to 13.6 N--m).

A. Replace brake shoes if damaged or if lining is

worn to 1/16” (1.6 mm). Replace if lining is contami-

nated by oil, grease, or other fluids.

4.

ver into slot and dust cover in backing plate.

Ifremovedfrombackingplate,slideparkingbrakele-

5.

Position brake shoes to backing plate. Make sure

NOTE: Overheated springs lose their tension, and

can cause brake linings to wear out prematurely.

that each shoe is properly positioned at anchor block,

parking brake lever, wheel cylinder and pin on adjuster

lever. Secure shoes to backing plate with shoe hold

down cups and springs.

B. Inspect brake shoe webbing, upper and lower

springs, and shoe hold down springs for overheat-

ing.Overheatingisindicatedbyaslightbluecolor.In-

spect brake shoe webbing for deformation. Replace

parts as necessary.

CAUTION

C. Inspect hold down pins on adjuster levers for

bends, rust and corrosion. Replace as necessary.

Be careful when installing springs to brake

shoes. The springs are under heavy load and

may cause personal injury.

3.

Inspect backing plate surfaces, which contact with

the brake shoes for grooves that may restrict shoe

movement. Replace plate if grooves can not be re-

moved by light sanding with emery cloth or other suit-

able abrasive. Replace plate if cracked, warped or

excessively rusted.

6.

Secure brake shoes with upper and lower springs.

4.

ers if deformation or excessive rust is found.

Inspect adjuster levers for deformation. Replace lev-

5.

Replace parking brake cables if frayed, stretched or

kinked.

Workman MDE

Page 4 -- 11

Transaxle and Brakes

| Categories | Lawn Mower Manual, Sprinkler and Irrigation Manuals, Toro Sprinkler and Irrigation Manuals |

|---|---|

| Download File |

|

| Document Type | Catalog |

| Language | English |

| Product Brand | Toro. Customer Service Representatives are available by phone:

Monday - Friday 7:30 a.m. to 9:00 p.m. (CDT) - Saturday 8:00 a.m. to 8:00 p.m. (CDT) - Sunday 10:00 a.m. to 8:00 p.m. (CDT)

Canada 1-888-225-4886 USA 1-888-384-9939, Lawn Mower |

| Document File Type | |

| Publisher | toro.com |

| Wikipedia's Page | Toro Company |

| Copyright | Attribution Non-commercial |

(0 votes, average: 0 out of 5)