Disassembly (Fig. 7)

Park machine on a level surface, fully raise coring

head, engage parking brake, stop engine and remove

key from the ignition switch. Secure coring head with

service latch.

E. Remove lock nut and cap screw that secure trac•

tion control cable to control lever. Locate and retrieve

two (2) flat washers. Loosen jam nut that secures

parking brake cable to underside of control handle.

1.

11.Inspect bearing cups and cones for wear or damage.

Replace worn or damaged components.

2.

Block rear wheels. Jack front of machine from

ground and support machine with blocking or jack

stands (see Operator’s Manual and Jacking Instructions

in Chapter 1 – Safety).

Assembly (Fig. 7)

1.

If removed, secure steering spindle to steering arm

with four (4) cap screws.

3.

in this section).

Remove front wheel assembly (see Wheel Removal

2.

cups to frame.

If bearing cups were removed from frame, install new

4.

moval in Service and Repairs section of Chapter 4 – Hy•

draulic System).

Remove front wheel motor (see Wheel Motor Re•

3.

Install steering arm to frame:

A. Pack bearing cones with grease. Position lower

bearing on steering spindle shaft.

5.

Remove fuel tank from machine (see Fuel Tank Re•

moval in Service and Repairs section of Chapter 3 –

Kohler Engine).

B. Slide steering shaft up through frame. Position

upper bearing and washer on steering spindle shaft.

6.

to steering arm. Position cables and wire harness away

from steering arm.

Remove two (2) cap screws that secure cable guide

C. Install slotted hex nut onto steering spindle, tight•

en completely and then back nut off slightly. Retigh•

ten nut until drag is felt while rotating steering arm.

Back–off nut to align spindle shaft hole with slotted

hex nut. Make sure that steering arm rotates freely

after slotted hex nut has been tightened.

7.

Support control handle. Remove three (3) lock nuts

that secure control handle to steering arm. Slide control

handle from steering arm taking care to not damage

control cables or wiring harness that will stay attached

to machine. Position handle away from steering arm.

D. Insert cotter pin through slotted hex nut and

steering spindle shaft.

8.

hex nut from upper end of steering spindle. Lower steer•

ing arm from frame.

Support steering arm. Remove cotter pin and slotted

4.

of disassembly using Figure 7 as a guide.

Assemble steering components in the reverse order

5.

from coring head before machine use.

Lower machine to ground. Remove service latch

9.

arm.

If necessary, remove steering spindle from steering

6.

cables or wire harness.

Make sure that steering components do not contact

10.If

necessary, remove control handle from machine:

A. Remove six (6) washer head screws that secure

lower handle cover to control handle. Remove lower

handle cover.

1

2

1

3

B. Remove four (4) screws that secure handle con•

trol cover to control handle. Unplug harness connec•

tors from low oil pressure light and raise lower switch

on cover.

C. Unplug harness connectors from neutral relay,

latching relay, neutral proximity switch and reverse

proximity switch on control handle.

D. Disconnect parking brake cable from brake lever

(see Parking Brake Cable Removal in this section).

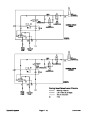

Figure 8

1.

2.

Relay

Reverse prox switch

3.

Neutral prox switch

ProCore 648

Page 6 – 11

Chassis

| Categories | Lawn Mower Manual, Sprinkler and Irrigation Manuals, Toro Sprinkler and Irrigation Manuals |

|---|---|

| Tags | Toro 648 |

| Download File |

|

| Document Type | Service Manual |

| Language | English |

| Product Brand | Toro. Customer Service Representatives are available by phone:

Monday - Friday 7:30 a.m. to 9:00 p.m. (CDT) - Saturday 8:00 a.m. to 8:00 p.m. (CDT) - Sunday 10:00 a.m. to 8:00 p.m. (CDT)

Canada 1-888-225-4886 USA 1-888-384-9939, Lawn Mower |

| Document File Type | |

| Publisher | toro.com |

| Wikipedia's Page | Toro Company |

| Copyright | Attribution Non-commercial |

(0 votes, average: 0 out of 5)