11.

Disconnect electrical connections from the following

engine components:

6

A. Disconnect ground cable to engine at starter/

generator terminal A1 (Fig. 15).

B. Disconnect engine harness connector from the

main harness.

5

1

2

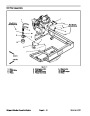

12.Remove

four (4) flange nuts and cap screws secur-

4

ing the engine to the engine tray.

3

CAUTION

One person should operate the hoist while the

other person guides the engine out of the frame.

Figure 16

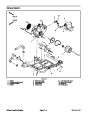

1.

2.

3.

Oil filter adapter

Oil filter

4.

5.

6.

Cap screw

Flange nut

Engine

13.Remove

engine from the engine tray.

Filter bracket

A. Attach a short section of chain between both en-

gine lift tabs.

3.

Install four (4) cap screws and flange nuts to engine

and engine tray. Position engine on engine tray to align

clutch drive pulley and driven pulley on transaxle. Tight-

en fasteners.

B. Connect hoist to center of chain.

IMPORTANT: Make sure to not damage the en-

gine,fuelhoses,electricalharnessorotherparts

while removing the engine.

4.

Carefully position oil filter assembly to filter bracket

(Fig. 16). Secure filter adapter with two (2) cap screws

and flange nuts.

C. Slowly remove engine from the machine.

5.

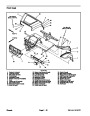

Connect the following electrical components:

14.Remove

engine parts and attachments as neces-

sary to repair the engine.

A. Connect ground cable from the engine at starter/

generator terminal A1 (Fig. 15).

Engine Installation (Fig. 12)

Install all removed parts and attachments to the en-

B. Connect engine harness connector to the main

harness connector.

1.

gine.

6.

Installstarter belttotheengineandstarter/generator

pulleys. Tension the belt by rotating the starter/genera-

tor away from the engine. Tighten fasteners to secure

starter/generator.

CAUTION

One person should operate the hoist while the

other person guides the engine into the frame.

7.

Install drive belt to drive clutch.

IMPORTANT: Make sure to remove all plugs and

covers that were placed on hose and engine open-

ings during engine removal.

2.

Install engine to the engine tray.

A. Attach a short section of chain between both en-

gine lift tabs.

8.

Install muffler and exhaust coupler to the machine

(see Exhaust System Installation in this section).

B. Connect a hoist at the center of the short section

of chain.

9.

Connect fuel inlet hose to the fuel pump (Fig. 13).

IMPORTANT: Make sure to not damage engine,

fuel lines, electrical harness or other parts while

installing the engine.

C. Carefully lower engine onto the engine tray.

Briggs & Stratton Gasoline Engine

Page 3 -- 16

Workman MDX

| Categories | Lawn Mower Manual, Sprinkler and Irrigation Manuals, Toro Sprinkler and Irrigation Manuals |

|---|---|

| Download File |

|

| Document Type | Service Manual |

| Language | English |

| Product Brand | Toro. Customer Service Representatives are available by phone:

Monday - Friday 7:30 a.m. to 9:00 p.m. (CDT) - Saturday 8:00 a.m. to 8:00 p.m. (CDT) - Sunday 10:00 a.m. to 8:00 p.m. (CDT)

Canada 1-888-225-4886 USA 1-888-384-9939, Lawn Mower |

| Document File Type | |

| Publisher | toro.com |

| Wikipedia's Page | Toro Company |

| Copyright | Attribution Non-commercial |

(0 votes, average: 0 out of 5)