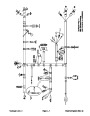

IMPORTANT: Do not attempt to disassemble the

piston block and spring. The parts are not service-

able separately. The rotating assembly (19) must be

replaced as an assembly.

8. Inspect the flat surface on the backplate (5); it should

be free of excessive scoring or metal build−up.

9.

Inspect the drive shaft (10) for fretting in the bearing

areas. Check spline area for twisted or broken teeth. If

keyed shaft, check for cracked or chipped keyway.

10.

11.

Remove camplate assembly (18) from housing.

Remove shaft seal (11) from housing.

Reassembly of Traction Motor

12.

Remove washer (12) and drive shaft (10) from hous-

1. Lubricate all critical moving parts before assembly.

ing.

2.

Install one retaining ring (13) in rear groove on drive

13.

(14),

Remove the two retaining rings (13), thrust races

and thrust bearing (15) from drive shaft (10).

shaft (10). Install one thrust race (14), thrust bearing

(15), and second thrust race (14) on drive shaft (10).

Install second retaining ring (13) in front groove on drive

shaft.

Inspection of Traction Motor

1.

2.

backplate (5). If the needles are free of excessive play

and remain in the bearing cage, there is not need to re-

place the bearing.

Wash all parts thoroughly in a suitable solvent.

3.

sary. Install shaft in housing assembly (17). Install wash-

er (12), shaft seal (11) and retain with retaining ring (9).

Replace needle bearing (16) in housing (17) if neces-

Examine bearings (16) and (7) in housing (17) and

4.

the piston block assembly.

Install the pivot, spider, and the piston assemblies in

3.

surfaces should be free of any signs of wear or fretting.

Inspect thrust races (14) and thrust bearing (15). All

5.

ing assembly with chamfered edge of race against

housing surface.

Lubricate camplate assembly (18) and install in hous-

4.

Inspect spider and pivot; conical surfaces should be

free of wear and score marks.

6.

Install piston block assembly in housing assembly.

The piston shoes must contact the camplate assembly

Be sure all parts are in their proper position.

5.

Inspect the pistons; the O.D. surface should be

(18).

smooth and free of scoring. The shoes should be snug

fit to the piston. The face of the shoes should be flat and

free of scoring and flaking. Do not lap piston shoes.

7.

8.

Install new bearing (7) in backplate (5) if necessary.

Install new O−ring (6) on backplate.

6.

Inspect the piston block; the bores should be free of

scoring. The surface that contacts the backplate should

be smooth and free of grooves or metal build−up.

9. Install backplate (5) on housing.

10.

Install capscrew (1 & 2) and torque 15−18 ft. lbs.

7.

Inspect the camplate assembly (18); the surface op-

posite the chamfered side should show no signs of scor-

ing.

Reelmaster 4000−D

Page 4 − 75

Hydraulic System

| Categories | Lawn Mower Manual, Sprinkler and Irrigation Manuals, Toro Sprinkler and Irrigation Manuals |

|---|---|

| Tags | Toro 4000 D, Toro 98958SL |

| Download File |

|

| Document Type | Catalog |

| Language | English |

| Product Brand | Toro. Customer Service Representatives are available by phone:

Monday - Friday 7:30 a.m. to 9:00 p.m. (CDT) - Saturday 8:00 a.m. to 8:00 p.m. (CDT) - Sunday 10:00 a.m. to 8:00 p.m. (CDT)

Canada 1-888-225-4886 USA 1-888-384-9939, Lawn Mower |

| Document File Type | |

| Publisher | toro.com |

| Wikipedia's Page | Toro Company |

| Copyright | Attribution Non-commercial |

(0 votes, average: 0 out of 5)