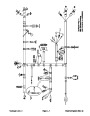

Disassembly of Reel Control Valve Assembly

5. Inspect seats in body for wear.

1.

2.

3.

4.

5.

6.

Plug all outlets and thoroughly clean outside of valve.

Remove plug (4) and O−ring (3).

Reassembly of Reel Control Valve Assembly

1. Thoroughly clean and dry all parts. Metal parts should

be lightly oiled prior to assembly.

Remove relief valve components (8, 7, 6, & 5).

Remove screws (22) and lock washers (23).

Remove detent block (25).

NOTE: All O−rings and back−up washers should be re-

placed as new parts.

2.

Position O−rings (5, 32, & 33) in body bore.

Remove detent plug (9), spring (10), and pawls (11)

3.

Install O−rings and back−up washers on relief valve

from detent block (25).

and plugs.

7.

Remove screw spool (26).

4.

Install plug (4).

8.

Remove shallow washer (27), wire washer (28),

5.

Install O−ring (32), washer (31), deep washer (30),

spring (29), deep washer (30), washer (31), and O−ring

(32).

spring (29), wire washer (28), and shallow washer (27)

into proper position in body casting.

9.

Remove spool (1).

6.

(26)

Insert spool (1) into body bore and screw spool screw

into spool.

10.

Remove all O−rings and back−up washers from all

plugs, relief valves, and body bore.

7.

Install spring (10), pawls (11), spring (10) and detent

plug (9) into detent block (25).

11.

Thoroughly clean all parts.

8.

cure to valve body (2) with lock washers (23) and cap

screws (22).

Slip detent block (25) over spool screw (26) and se-

Inspection of Reel Control Valve Assembly

1.

2.

Remove nicks and burrs from all parts.

9.

Install relief valve (8).

Inspect spool and body bore for excessive wear.

10.

Run operational check.

NOTE: If internal leakage with the spools in spring−

centered position has been experienced, wear is indi-

cated between the spool and body bore. This can be

corrected by replacing the spool and body as an as-

sembly. Spools or bodies cannot be serviced separately.

3.

Inspect relief valve.

NOTE: The pilot−operated cartridge−type relief valve is

not adjustable and is pre−set at the factory. However, to

ensure cleanliness in the system; snap ring, washer,

and screens may be removed, cleaned with air, and re-

placed.

4.

Inspection of O−rings and back−up washers is not ne-

cessary. It is recommended that these be replaced as

new parts.

Reelmaster 4000−D

Page 4 − 65

Hydraulic System

| Categories | Lawn Mower Manual, Sprinkler and Irrigation Manuals, Toro Sprinkler and Irrigation Manuals |

|---|---|

| Tags | Toro 4000 D, Toro 98958SL |

| Download File |

|

| Document Type | Catalog |

| Language | English |

| Product Brand | Toro. Customer Service Representatives are available by phone:

Monday - Friday 7:30 a.m. to 9:00 p.m. (CDT) - Saturday 8:00 a.m. to 8:00 p.m. (CDT) - Sunday 10:00 a.m. to 8:00 p.m. (CDT)

Canada 1-888-225-4886 USA 1-888-384-9939, Lawn Mower |

| Document File Type | |

| Publisher | toro.com |

| Wikipedia's Page | Toro Company |

| Copyright | Attribution Non-commercial |

(0 votes, average: 0 out of 5)