Engine Installation

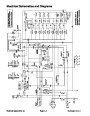

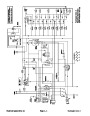

C. Connect red/black wire to the glow plug bus bar

(Fig. 23).

CAUTION

8. Connect the following fuel hoses:

A. Suction hose at the injector pump from the fuel

filter. Suction and discharge hoses at the fuel pump

(Fig. 22).

One person should operate lift or hoist while the

other person guides the engine into the frame.

B. Return hose from the fuel injectors (Fig. 23).

C. Remove clamps used to prevent drainage.

1.

brackets.

Install engine to the front engine mounts and rear

A. Attach a hoist or lift to the engine.

9. Position fan shroud to the radiator. Install fan to the

fan pulley (Fig. 21).

IMPORTANT: Make sure not to damage the engine,

fuel and hydraulic lines, electrical harness, or other

parts while installing the engine.

A. Apply Loctite (Blue) 242 or equivalent to the

ends of the cap screws.

B. Place gasket onto exhaust bracket to receive ex-

haust tube (Fig. 26).

B. Torque cap screws from 80 to 110 in−lb (92 to

127 kg−cm).

C. Lower engine slowly into the machine.

10. Install fan shroud and guard to the radiator (Fig. 20).

11. Install exhaust shield to the engine (Fig. 20).

2.

Secure both front brackets to the engine mounts

with cap screw, flat washers, spring washer, and hex nu.

Torque cap screw and hex nut from 59 to 73 ft−lb (8.2 to

12.

Install air hose to air intake manifold (Fig. 20).

10.1

kg−m)t (Fig. 26).

13.

Install battery the machine and connect cables (see

Battery Service in Chapter 5 − Electrical Systems).

3.

Secure engine to the spacers and rear brackets with

three cap screws and lock washers. Torque cap screws

from 61 to 75 ft−lb (8.4 to 10.4 kg−m) (Fig. 27).

14.

15.

16.

Connect both hoses to the radiator (Fig. 20).

Secure canopy to the brackets (Fig. 19).

4.

Secure exhaust tube and gasket to the exhaust

bracket with three cap screws and lock nuts (Fig. 26).

Fill radiator with coolant (see Check Cooling Sys-

tem).

5.

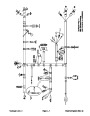

Connect hydraulic pump assembly to the engine

(Fig. 25).

17.

Adjust control cable throttle cable (Fig. 24).

A. Position the pump shaft into the spring coupling.

A. Push throttle lever to the FAST position.

B. Secure pump mounting flange to the pump

adapter plate with four cap screws, flat washers,

and lock washers. Torque cap screws from 60 to 80

ft−lb (8.3 to 11.1 kg−m).

B. Loosen screw on swivel that secures the cable to

the swivel lever.

C. Adjust position of swivel lever with cable so the

injector pump lever is contacting the stop in the full

throttle position.

C. Connect damper to the bracket.

6.

Secure cable to engine plate with R−clamp (Fig. 24).

Connect throttle control cable to the swivel lever.

D. Secure cable to swivel with screw.

18.

19.

Prime fuel system (see Prime Fuel System).

Check traction pedal adjustment for NEUTRAL.

7.

gine as follows:

Connect wire harness and electrical wires to the en-

A. Connect wire and connector to the alternator,

red cable to starter, three wires to the starter, wire to

the oil pressure switch, and wires to high tempera-

ture warning and shutdown switches (Fig. 20).

B. Connect electrical connector to the fuel solenoid

(Fig. 22).

Kubota Diesel Engine

Reelmaster 4000−D

Page 3 − 16

| Categories | Lawn Mower Manual, Sprinkler and Irrigation Manuals, Toro Sprinkler and Irrigation Manuals |

|---|---|

| Tags | Toro 4000 D, Toro 98958SL |

| Download File |

|

| Document Type | Catalog |

| Language | English |

| Product Brand | Toro. Customer Service Representatives are available by phone:

Monday - Friday 7:30 a.m. to 9:00 p.m. (CDT) - Saturday 8:00 a.m. to 8:00 p.m. (CDT) - Sunday 10:00 a.m. to 8:00 p.m. (CDT)

Canada 1-888-225-4886 USA 1-888-384-9939, Lawn Mower |

| Document File Type | |

| Publisher | toro.com |

| Wikipedia's Page | Toro Company |

| Copyright | Attribution Non-commercial |

(0 votes, average: 0 out of 5)