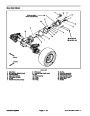

4WD Manifold Service (Fig. 60)

Make sure the manifold is clean before removing the

7. The 4WD control manifold includes three (3) orifice

fittings (items 9 and 13). The 0.030 orifice (item 9) is

positioned in the SV port under the solenoid cartridge

valve. The 0.050 orifices (item 13) thread into the man-

ifold in ports OR1 and OR2. Before removing or instal-

ling the orifice in OR1, removal of the #6 plug in the

bottom of the manifold is necessary.

1.

valve.

2.

ing solenoid to the cartridge valve. Carefully slide sole-

noid off the valve.

If cartridge is solenoid operated, remove nut secur-

8.

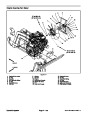

Reinstall the cartridge valve:

IMPORTANT: Use care when handling the valvecar-

tridge. Slight bending or distortion of the stem tube

can cause binding and malfunction.

A. Lubricate new seal kit components with clean hy-

draulic oil and install on valve. The O--rings, sealing

ringsandbackupringsmustbearrangedproperlyon

the cartridge valve for proper operation and sealing.

3.

Note correct location for O--rings, sealing rings and

backup rings. Remove and discard seal kit.

Remove cartridge valve with a deep socket wrench.

IMPORTANT: Use care when handling the valve

cartridge. Slight bending or distortion of the

stem tube can cause binding and malfunction.

4.

tothesealingsurfaces,damagedthreads orcontamina-

tion.

Visually inspect the port in the manifold for damage

B. Thread cartridge valve carefully into manifold

port. The valve should go in easily without binding.

5.

Visually inspect cartridge valve for damaged sealing

surfaces and contamination.

C. Torquecartridgevalveusingadeepsockettoval-

ue identified in manifold illustration.

A. Contamination may cause valves to stick or hang

up.Contaminationcanbecomelodgedinsmallvalve

orifices or seal areas causing malfunction.

D. If cartridge is solenoid operated, carefully install

solenoid coil to the cartridge valve. Torque nut to val-

ue identified in manifold illustration.

B. If valve sealing surfaces appear pitted or dam-

aged, the hydraulic system may be overheating or

there may be water in the system.

9.

If problems still exist, remove valve and clean again

or replace valve.

CAUTION

Use eye protection such as goggles when using

compressed air.

6.

Clean cartridge valve using clean mineral spirits.

Submerge valve in clean mineral spirits to flush out con-

tamination.Particlesasfineastalcumpowdercanaffect

the operation of high pressure hydraulic valves. If car-

tridgedesignallows,useawoodorplasticprobetopush

the internal spool in and out 20 to 30 times to flush out

contamination. Be extremely careful not to damage car-

tridge. Use compressed air for cleaning.

Groundsmaster 4000--D

Page 4 -- 87

Hydraulic System

| Categories | Lawn Mower Manual, Sprinkler and Irrigation Manuals, Toro Sprinkler and Irrigation Manuals |

|---|---|

| Tags | Toro Groundsmaster 30412, Toro Groundsmaster 4000 D |

| Download File |

|

| Document Type | Catalog |

| Language | English |

| Product Brand | Toro. Customer Service Representatives are available by phone:

Monday - Friday 7:30 a.m. to 9:00 p.m. (CDT) - Saturday 8:00 a.m. to 8:00 p.m. (CDT) - Sunday 10:00 a.m. to 8:00 p.m. (CDT)

Canada 1-888-225-4886 USA 1-888-384-9939, Lawn Mower |

| Document File Type | |

| Publisher | toro.com |

| Wikipedia's Page | Toro Company |

| Copyright | Attribution Non-commercial |

(0 votes, average: 0 out of 5)