NOTE: The front frame needs to be lowered from the

main frame to allow clearance to remove the hydraulic

reservoir from the machine.

Inspection

1.

Clean hydraulic reservoir and suction strainer with

solvent.

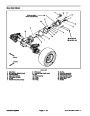

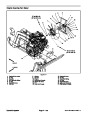

Removal (Fig. 47)

2.

Inspect reservoir for leaks, cracks or other damage.

1.

decks, stop engine, apply parking brake and remove

key from the ignition switch.

Park machine on a level surface, lower cutting

Installation (Fig. 47)

1.

Using a wrench, turn tank strainer into port at least

to 2 full turns beyond finger tight.

1--1/2

2.

Remove front cutting deck (see Front Cutting Deck

Removal in the Service and Repairs section of Chapter

2.

Position reservoir to machine.

8

-- Cutting Decks).

3.

Align frame mounting holes and support front frame to

prevent it from moving.

Carefully raise front frame assembly to main frame.

3.

Installing Hydraulic System Components at the begin-

ning of the Service and Repairs section of this chapter.

Read the General Precautions for Removing and

4.

(item 35), flat washers (item 28) and flange nuts (item

30).

Secure front frame to main frame with cap screws

4.

5.

Drain reservoir into a suitable container.

Disconnect hydraulic hoses from reservoir. Label

disconnected hydraulic lines for proper installation.

5.

6.

Lower machine to ground.

6.

Remove straps (items 4 and 8) that secure reservoir

to front frame. Remove felt straps (item 3) from between

straps and reservoir.

Position felt straps (item 3) between straps and res-

ervoir. Secure reservoir to front frame with straps (items

4

and 8).

7.

To allow front frame to be lowered for reservoir re-

7.

Remove caps and plugs from hydraulic lines and fit-

moval, remove hydraulic tubes that connect hydraulic

components on front frame (wheel motors, front deck

PTO manifold and traction manifold) to components on

main frame. Put caps or plugs on open hydraulic lines

and fittings.

tings that were placed during the removal process. Us-

ing labels placed during removal, connect hydraulic

hoses and tubes to fittings on reservoir, wheel motors

and hydraulic manifolds (see Hydraulic Hose and Tube

Installation in the General Information section of this

chapter).

8.

Chockrearwheelstopreventthemachinefrommov-

ing. Use jack or hoist to raise front of machine and sup-

port machine with jackstands.

8.

Installation in the Service and Repairs section of Chap-

ter 8 -- Cutting Decks).

Install front cutting deck (see Front Cutting Deck

9.

Support front frame to prevent it from moving.

capscrews (item 35), flatwashers (item 28)

9.

Fill reservoir with new hydraulic fluid to proper level.

fill hydraulic system (see Charge Hydraulic

10.Remove

and flange nuts (item 30) thatsecure front frame tomain

frame.

10.Properly

System in this section).

11.

ance for reservoir removal. Once lowered, support front

frame to prevent it from shifting.

Carefully lower front frame assembly to allow clear-

11.

hydraulic reservoir oil level.

Stop engine and check for hydraulic oil leaks. Check

12.Carefully

remove hydraulic reservoir from machine.

Groundsmaster 4000--D

Page 4 -- 65

Hydraulic System

| Categories | Lawn Mower Manual, Sprinkler and Irrigation Manuals, Toro Sprinkler and Irrigation Manuals |

|---|---|

| Tags | Toro Groundsmaster 30412, Toro Groundsmaster 4000 D |

| Download File |

|

| Document Type | Catalog |

| Language | English |

| Product Brand | Toro. Customer Service Representatives are available by phone:

Monday - Friday 7:30 a.m. to 9:00 p.m. (CDT) - Saturday 8:00 a.m. to 8:00 p.m. (CDT) - Sunday 10:00 a.m. to 8:00 p.m. (CDT)

Canada 1-888-225-4886 USA 1-888-384-9939, Lawn Mower |

| Document File Type | |

| Publisher | toro.com |

| Wikipedia's Page | Toro Company |

| Copyright | Attribution Non-commercial |

(0 votes, average: 0 out of 5)