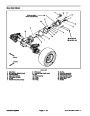

Removal (Fig. 71)

Park machine on a level surface, lower cutting

decks, stop engine, apply parking brake and remove

key from the ignition switch.

IMPORTANT: Make sure to not damage the radiator,

oil cooler or other machine components while

installing the fan motor.

1.

2. Carefully position fan motor to fan motor bracket.

Loosely attach motor to bracket with cap screws (item

2.

Installing Hydraulic System Components at the begin-

ning of the Service and Repairs section of this chapter.

Read the General Precautions for Removing and

20),

flat washers (item 21) and lock nuts (item 14).

3. Remove caps or plugs placed during removal to pre-

vent contamination. Connect hydraulic hoses to cooling

fan motor (see Hydraulic Hose and Tube Installation in

the General Information section of this chapter).

3.

Unlatch and raise hood.

4.

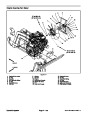

Remove air cleaner hose and upper radiator shroud

to allow easier access to hydraulic fan motor (Fig. 72).

4.

5.

shaft and fan hub. Position fan hub (with fan attached)

onto motor shaft and secure with washer (item 8) and

hex nut (item 9). Torque nut from 27 to 33 ft--lb (37 to

44 N--m).

Tighten fasteners to secure fan motor to bracket.

Thoroughly clean tapered surfaces of fan motor

CAUTION

The radiator and oil cooler may be hot. To avoid

possible burns, allow the engine and cooling

systems to cool before removing fan motor.

6. Install upper radiator shroud and air cleaner hose

(Fig.72).Makesurethatclearance between shroudand

cooling fan is at least 0.180” (4.6 mm) at all points.

IMPORTANT: Make sure to not damage the radiator,

fan or other machine components while loosening

and removing the fan motor.

7.

Lower and secure hood.

5.

cure fan hub and fan assembly to fan motor.

Removehexnut(item9)andwasher(item8)thatse-

1

2

6.

Use suitable puller to remove fan hub (with fan at-

tached) from fan motor shaft taking care to not damage

fan. Position fan assembly away from fan motor.

3

4

7.

fan motor removal, thoroughly clean exterior of motor

and fittings.

To prevent contamination of hydraulic system during

5

8.

Put caps or plugs on fittings and hoses to prevent con-

tamination. Tag hydraulic lines for proper assembly.

Disconnect hydraulic hoses from cooling fan motor.

4

9.

Support fan motor to prevent it from falling. Remove

6

two (2) cap screws (item 20), flat washers (item 21) and

lock nuts (item 14) that secure fan motor to fan motor

bracket.

7

4

Figure 72

10.Carefully

lower fanmotor andremove frommachine.

1.

Radiator

5.

6.

7.

Air cleaner hose

Flange nut (4 used)

Cap screw

2.

3.

4.

Upper radiator shroud

Screw (4 used)

Flat washer

11.

If hydraulic fittings are to be removed from fan motor,

mark fitting orientation to allow correct assembly. Re-

move fittings from motor and discard O--rings.

Installation (Fig. 71)

1.

Iffittings were removed fromfan motor,lubricate and

place new O--rings onto fittings. Install fittings into port

openingsusingmarksmadeduringtheremovalprocess

to properly orientate fittings. Tighten fittings (see Hy-

draulic Fitting Installation in the General Information

section of this chapter).

Groundsmaster 4000--D

Page 4 -- 107

Hydraulic System

| Categories | Lawn Mower Manual, Sprinkler and Irrigation Manuals, Toro Sprinkler and Irrigation Manuals |

|---|---|

| Tags | Toro Groundsmaster 30412, Toro Groundsmaster 4000 D |

| Download File |

|

| Document Type | Catalog |

| Language | English |

| Product Brand | Toro. Customer Service Representatives are available by phone:

Monday - Friday 7:30 a.m. to 9:00 p.m. (CDT) - Saturday 8:00 a.m. to 8:00 p.m. (CDT) - Sunday 10:00 a.m. to 8:00 p.m. (CDT)

Canada 1-888-225-4886 USA 1-888-384-9939, Lawn Mower |

| Document File Type | |

| Publisher | toro.com |

| Wikipedia's Page | Toro Company |

| Copyright | Attribution Non-commercial |

(0 votes, average: 0 out of 5)