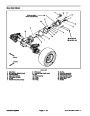

Removal (Fig. 2)

Park machine on a level surface, lower cutting

decks, stop engine, apply parking brake and remove

key from the ignition switch.

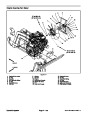

6. If removed, install ball joint to lift arm. Distance from

endofliftarmtocenter ofballjointshouldbefrom2.210”

to 2.390” (56.1 to 60.7 mm) (Fig. 4). Make sure that ball

joint is horizontal and that stud is centered in ball joint.

Install deck before torquing ball joint jam nut (item 24).

1.

2.

Removal in Chapter 8 -- Cutting Decks).

Remove front cutting deck (see Front Cutting Deck

7.

Torque nut from 90 to 100 ft--lb (123 to 135 N--m) while

Installballjointmounttoballjointwithslottedhexnut.

aligning cotter pin holes. Install cotter pin.

CAUTION

8. Install front cutting deck (see Front Cutting Deck

Installation in Chapter 8 -- Cutting Decks).

When changing attachments, tires or perform-

ing other service, use correct jacks and sup-

ports. Make sure machine is parked on a solid,

level surface such as a concrete floor. Prior to

raising machine, remove any attachments that

may interfere with the safe and proper raising of

themachine.Alwayschockorblockwheels.Use

jack stands to support the raised machine. If the

machine is not properly supported by jack

stands, the machine may move or fall, which

may result in personal injury.

9. Ifballjointwasremoved fromliftarm,torqueballjoint

jam nut from 150 to 175 ft--lb (203 to 237 N--m).

10.Lubricate

lift arm grease fittings.

11.

Afterassemblyiscompleted,raiseandlowerthecut-

tingdecktoverifythathydraulichosesandfittingsdonot

contact anything.

12.Check

height--of--cut and deck pitch adjustment.

1

3.

Chock rear wheels and jack up front of machine.

Support machine on jack stands.

4.

Remove front wheel next to lift arm that is to be re-

moved.

2

0.870”

(22.1

mm)

5.

Remove cap screw, washers and lock nut that se-

cure liftcylinder pin to liftarm. Remove pin and separate

lift cylinder and lift arm.

6.

arm and slide pin from frame and lift arm. Remove lift

arm from frame.

Remove lock nut that secures lift arm pin. Support lift

Figure 3

2.

1.

U--bolt

Height--of--cut chain

7.

ball joint from removed lift arm as required.

Remove height--of--cut chain, ball joint mount and

Installation (Fig. 2)

1.

gage roll pin into frame slots and install lock nut on pin.

Position lift arm to frame and insert lift arm pin. En-

Torque lock nut from 60 to 70 ft--lb (81 to 94 N--m).

2.

arm and cylinder end. Secure pin with cap screw, wash-

ers and lock nut.

Align lift cylinder with lift arm. Slide pin through lift

1

2

3.

4.

5.

Install front wheel assembly.

Lower machine to the ground.

2.210”

to 2.390”

If height--of--cut chain u--bolt was removed from lift

(56.1 to 60.7 mm)

arm, assemble u--bolt so that threaded portion extends

0.870”

3).

(22.1 mm) above mounting plate on lift arm (Fig.

Figure 4

2.

1.

Lift arm

Ball joint

Groundsmaster 4000--D

Page 7 -- 5

Chassis

| Categories | Lawn Mower Manual, Sprinkler and Irrigation Manuals, Toro Sprinkler and Irrigation Manuals |

|---|---|

| Tags | Toro Groundsmaster 30412, Toro Groundsmaster 4000 D |

| Download File |

|

| Document Type | Catalog |

| Language | English |

| Product Brand | Toro. Customer Service Representatives are available by phone:

Monday - Friday 7:30 a.m. to 9:00 p.m. (CDT) - Saturday 8:00 a.m. to 8:00 p.m. (CDT) - Sunday 10:00 a.m. to 8:00 p.m. (CDT)

Canada 1-888-225-4886 USA 1-888-384-9939, Lawn Mower |

| Document File Type | |

| Publisher | toro.com |

| Wikipedia's Page | Toro Company |

| Copyright | Attribution Non-commercial |

(0 votes, average: 0 out of 5)