Differential Gear Installation

If the ring gear was removed from the differential

3

1.

2

case, use medium strength Loctite thread locker and

tighten the mounting screws from 22 to 25 ft-lb (30 to

34

N--m).

1

2.

1901

Apply molybdenum disulfide lubricant (Three Bond

or equivalent) to the splines and bearing surfaces

of the differential pinion gears, pinion washers and side

gears.

3.

original location in the differential case.

Install the side gear shims and side gears in their

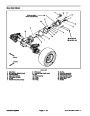

Figure 39

1.

2.

Vise

Differential gear case

3. Dial indicator

4.

ers in their original location in the differential case. Tem-

porarily install the differential pinion shaft.

Place the differential pinion gears and pinion wash-

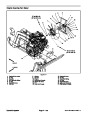

More than 35% total tooth contact

5.

Securethedifferentialcaseinasoftjawedvise.Posi-

tion a dial indicator on a tooth of the differential pinion

gear.Pressthepinionandsidegearagainstthedifferen-

tial case and measure the pinion gear to side gear back-

lash (Fig. 39).

PINION GEAR TO SIDE GEAR BACKLASH:

1/3

from small end of tooth

to 1/2 of entire width

0.004

to 0.016 in. (0.10 to 0.40 mm)

6.

shim thickness.

Adjust backlash by increasing or reducing side gear

Figure 40

12.Install

support half.

differential gear assembly in right side axle

NOTE: Side gear shims are available in 0.043 in. (1.10

mm), 0.047 in. (1.20 mm) and 0.051 in. (1.30 mm) thick-

ness.

13.Coat

a new O-ring with grease and install left side

axlesupporthalf.Tightenaxlesupportcasescrewsfrom

7.

Steel Blue lightly over several gear teeth.

Apply gear marking compound, such as DyKemR

35

to 41 ft-lb (47 to 56 N--m).

14.Install

Shaft/Pinion Gear in this section of this manual).

input shaft/pinion gear assembly (see Input

8.

either pinion gear until the side gears have made one

complete revolution.

While applying a light load to either side gear, rotate

15.Coat

new O-rings with grease, align differential shaft

splines with differential gear assembly and slide differ-

ential shaft assemblies onto axle support.

9.

Ideal tooth contact should cover more than 35% of

each tooth surface. The contact area should be in the

center of each tooth and extend 1/3 to 1/2 way across

each tooth from the toe (small) end (Fig. 40).

16.Install

bevel gear case/axle case assemblies (see

Bevel Gear Case/Axle Case Assembly in this section of

this manual).

10.Adjust

side gear shims if necessary to correct tooth

contact. Recheck differential pinion gear to side gear

backlash if any changes are made.

11.

After backlash and tooth contact have been ad-

justed, align the hole in the differential pinion shaft with

the hole in the differential case and install a new spring

pin.

Axles, Planetaries and Brakes

Page 6 -- 28

Groundsmaster 4000--D

| Categories | Lawn Mower Manual, Sprinkler and Irrigation Manuals, Toro Sprinkler and Irrigation Manuals |

|---|---|

| Tags | Toro Groundsmaster 30412, Toro Groundsmaster 4000 D |

| Download File |

|

| Document Type | Catalog |

| Language | English |

| Product Brand | Toro. Customer Service Representatives are available by phone:

Monday - Friday 7:30 a.m. to 9:00 p.m. (CDT) - Saturday 8:00 a.m. to 8:00 p.m. (CDT) - Sunday 10:00 a.m. to 8:00 p.m. (CDT)

Canada 1-888-225-4886 USA 1-888-384-9939, Lawn Mower |

| Document File Type | |

| Publisher | toro.com |

| Wikipedia's Page | Toro Company |

| Copyright | Attribution Non-commercial |

(0 votes, average: 0 out of 5)