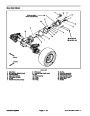

Traction Circuit: Transport (2WD)

The traction circuit piston pump is a variable displace-

ment pump that is directly coupled to the engine fly-

wheel. Pushing the traction pedal engages a hydraulic

servo valve which controls the variable displacement

piston pump swash plate to create a flow of oil. This oil

isdirectedtothefrontwheelandrearaxlemotors.Oper-

ating pressure on the high pressure side of the closed

traction circuit loop is determined by the amount of load

developedatthefixeddisplacementwheelandaxlemo-

tors. As the load increases, circuit pressure can in-

crease to relief valve settings: 4000 PSI (274 bar) in

forward and 5000 PSI (343 bar) in reverse. If pressure

exceeds the relief setting, oil flows through the relief

valve to the low pressure side of the closed loop traction

circuit. The traction circuit provides operation in either

4WD (mow) or transport (2WD).

Forward Direction

With the transport/4WD switch in the transport position,

solenoid valve (SV) in the 4WD control manifold is ener-

gized. The solenoid valve spool shifts to direct charge

pressure that shifts the PD1 and PD2 control valve

spools. The shifted PD1 valve prevents hydraulic flow

from the piston pump to the rear axle motor. With flow

blocked to the rear axle motor, all pump flow is directed

to the front wheel motors to allow a higher transport

speed in the forward direction.

Without flow to the rear axle motor, the rotating rear

wheels drive the axle motor so it acts like a pump. Inlet

oil to the axle motor is provided by a check valve that al-

lows charge oil into the rear axle motor circuit. Oil leav-

ing the axle motor enters the 4WD control manifold at

port M2 and is directed back to the axle motor through

the shifted PD1 cartridge and manifold port M1. Toallow

forrearwheelloopcoolingwheninforwardtransportop-

eration, a small amount of oil exits through the shifted

PD1 and PD2 cartridges that returns to the reservoir.

Traction circuit pressure (forward and reverse) can be

measured at test ports on the sides of the machine.

The traction circuit pump and motors use a small

amount of hydraulic fluid for internal lubrication. Fluid is

designed to leak across traction pump and motor com-

ponents into the case drain. This leakage results in the

lossofhydraulicfluidfromtheclosedlooptractioncircuit

that must be replaced. The charge circuit is designed to

replace this traction circuit leakage.

A transport cylinder is included in the traction circuit to

reduce traction control arm movement on the piston

pump when operating in transport (2WD). This reduced

arm movement limits swash plate rotation topreventex-

cessive transport speed.

The gear pump section that supplies oil to the steering

and lift/lower circuits also provides charge oil for the

traction circuit. This gear pump is driven directly off the

tractionpump.Itprovidesaconstantsupplyofchargeoil

to the traction circuit to make up for oil that is lost due to

internal leakage in the traction pump and motors.

The tractionmanifold flowdivider cannotbe engaged by

the operator during transport (2WD) operation.

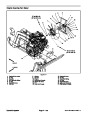

Reverse Direction

The traction circuit operates essentially the same in re-

versetransport(2WD)asitdoesintheforwarddirection.

However, the flow through the circuit is reversed. The

shifted solenoid valve (SV) and directional valves PD1

and PD2 in the 4WD manifold prevent oil flow from the

rear axle motor. Oil flow from the hydrostat is therefore

directed to only the front wheel motors. This oil drives

the front wheel motors in the reverse direction and then

returns to the hydrostat. Oil circulation through the rear

axle motor loop is the same as in the transport (2WD)

forward direction.

Charge pump flow is directed through the oil filter and to

the low pressure side of the closed loop traction circuit.

A filter bypass valve allows charge oil flow to the closed

loop if the filter becomes plugged. Charge pressure is li-

mited to 250 PSI (17 bar) by a relief valve located in the

oil filter manifold. Charge pressure can be measured at

the charge circuit pressure test port on the oil filter man-

ifold.

Groundsmaster 4000--D

Page 4 -- 13

Hydraulic System

| Categories | Lawn Mower Manual, Sprinkler and Irrigation Manuals, Toro Sprinkler and Irrigation Manuals |

|---|---|

| Tags | Toro Groundsmaster 30412, Toro Groundsmaster 4000 D |

| Download File |

|

| Document Type | Catalog |

| Language | English |

| Product Brand | Toro. Customer Service Representatives are available by phone:

Monday - Friday 7:30 a.m. to 9:00 p.m. (CDT) - Saturday 8:00 a.m. to 8:00 p.m. (CDT) - Sunday 10:00 a.m. to 8:00 p.m. (CDT)

Canada 1-888-225-4886 USA 1-888-384-9939, Lawn Mower |

| Document File Type | |

| Publisher | toro.com |

| Wikipedia's Page | Toro Company |

| Copyright | Attribution Non-commercial |

(0 votes, average: 0 out of 5)