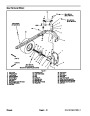

Piston Pump Removal (Fig. 51)

Park machine on a level surface, lower cutting units,

stop engine, engage parking brake and remove key

from the ignition switch.

11.If hydraulic fittings are to be removed from piston

pump, mark fitting orientation to allow correct assembly.

Remove hydraulic fittings and o--rings from the piston

pump as needed.

1.

12.Remove

pulley from the taper lock bushing:

2.

Remove traction belt from the pulley (see Traction

Unit Operator’s Manual).

A. Remove three (3) cap screws (item 36) and lock

washers (item 37) securing pulley to the taper lock

bushing.

3.

Remove neutral arm assembly from the piston pump

(see Neutral Arm Assembly Removal in this section).

IMPORTANT: Excessive or unequal pressure on

the cap screws can break the bushing flange.

4.

Unit Operator’s Manual).

Drain hydraulic oil from Hydraulic tank (see Traction

B. Insert cap screws into threaded removal holes of

the pulley. Tighten screws progressively and evenly

until the pulley is loose on the bushing. Remove

pulley from the bushing.

5.

pistonpumptopreventhydraulicsystemcontamination.

Thoroughlycleanhydraulichoseendsandfittingson

WARNING

13.Loosen

set screw that secures taper lock bushing to

piston pump. Remove bushing from the pump shaft. Lo-

cate and retrieve key from pump shaft.

Before disconnecting or performing any work

on the hydraulic system, all pressure in the

system must be relieved. See Relieving Hy-

draulic System Pressure in the General Infor-

mation section.

14.Remove

both cap screws (item 26) and washers

(item 10) thatsecure pistonpump topump support (item

Locate and retrieve spacers (item 29).

28).

15.Remove

locknuts(item4),flatwashers(item46)and

cap screws (item 3) that secure the piston pump to the

pump mount plate. Remove pump from plate.

6.

purposes.

Label all hydraulic hoses and fittings for assembly

Piston Pump Installation (Figs. 51)

7.

Disconnect all hydraulic hoses connected to the hy-

draulic fittings on the piston and gear pumps. Allow

hoses todraininto asuitable container.Plug hoseopen-

ings to prevent contamination.

1.

platewithflatwashers(item46),capscrews(item3)and

lock nuts (item 4).

Position and secure piston pump to the pump mount

CAUTION

Support piston and gear pumps when removing

them from the pump support and pump mount

plate to prevent them from falling and causing

personal injury.

1

8.

flangenuts(item25)thatsecure pumpsupport(item28)

to engine mount (item 58).

Remove both flange head screws (item 27) and

3

6

9.

Remove fasteners and spacers securing the pump

mount plate to the engine (Fig. 52). Note location of cap

screws, washers and spacers for assembly purposes.

Pull pump mount plate with pumps, pump pulley, pump

support and idler assembly from the machine.

1

4

5

2

3

10.Remove

both cap screws (item 56) and flat washers

Figure 52

(item 55) securing gear pump to the piston pump. Sepa-

rate gear pump from the piston pump. Locate and re-

trieve o--ring (item 54). Plug openings of gear pump to

prevent contamination.

1.

2.

3.

Long spacer (4 used)

Flat washer (3 used)

Cap screw (4 used)

4.

5.

6.

Flat washer

Cap screw

Short spacer

Groundsmaster 3505--D

Page 4 -- 81

Hydraulic System

| Categories | Lawn Mower Manual, Sprinkler and Irrigation Manuals, Toro Sprinkler and Irrigation Manuals |

|---|---|

| Tags | Toro Groundsmaster 3505 D |

| Download File |

|

| Document Type | Service Manual |

| Language | English |

| Product Brand | Toro. Customer Service Representatives are available by phone:

Monday - Friday 7:30 a.m. to 9:00 p.m. (CDT) - Saturday 8:00 a.m. to 8:00 p.m. (CDT) - Sunday 10:00 a.m. to 8:00 p.m. (CDT)

Canada 1-888-225-4886 USA 1-888-384-9939, Lawn Mower |

| Document File Type | |

| Publisher | toro.com |

| Wikipedia's Page | Toro Company |

| Copyright | Attribution Non-commercial |

(0 votes, average: 0 out of 5)