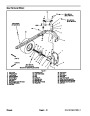

Blade Spindle Service

Disassembly (Fig. 15)

2

1.

shaft.

Loosen and remove spindle nut from top of spindle

6

4

2.

ing an arbor press. The shaft spacer remains on the

spindle shaft as the shaft is being removed.

Press thespindle shaft outofthespindle housing us-

130

(176

to 160 ft--lb

to 216 N--m)

11

10

9

3.

4.

Remove seals from spindle housing.

12

7

8

Allow the bearings, inside spacer and spacer ring to

fall out of the spindle housing.

1

5.

cups out of the spindle housing. Also drive the large

spacer out of the housing.

Usingapunchandhammer,drivebothofthebearing

4

5

6.

housing because it is difficult to remove.

The large snap ring should remain inside the spindle

Assembly (Fig. 15)

3

IMPORTANT: If new bearings will be installed into a

used spindle housing it may not be necessary to re-

place the original large snap ring. If the original

snap ring is in good condition with no evidence of

damage (e.g. spun bearing), leave the snap ring in

the housing and discard the snap ring that came

with the new bearings. However, new bearings with

their matched spacer set and large snap ring must

ALWAYS be installed when the spindle housing is

beingreplaced.Replacementbearingsaresoldonly

with a matched snap ring and spacer set (Fig. 16).

These parts cannot be purchased separately.

Figure 15

1.

2.

3.

4.

5.

6.

Spindle housing

Spindle plug

Spindle shaft

Oil seal

Shaft spacer

Spindle nut

7.

8.

9.

Grease fitting

Bearing

Spacer ring

10. Spacer set (2 piece)

11. Bearing

12. Large snap ring

1

4

1.

If large snap ring was removed or if replacing the

spindle housing, install large snap ring into spindle

housing groove. Make sure snap ring is seated in

groove.

2

3

IMPORTANT: If bearings are being replaced, make

sure to use the large spacer, inside spacer and

spacer ring that are included in new bearing set.

5

1

2.

spindlehousing.Thespacershouldfittightly againstthe

large snap ring.

Using an arbor press, push large spacer into top of

Figure 16

1.

2.

3.

Bearing

Spacer ring

Large snap ring

4. Inner spacer

5. Outer spacer

3.

Thoroughly oil the bearing cups. Using an arbor

press, push the bearing cups into the top and bottom of

the spindle housing. The top bearing cup must contact

the spacer previously installed and the bottom bearing

cup must contact the snap ring. Make sure that the as-

sembly is correct by supporting the first bearing cup and

pressing the second against it (Fig 17).

Cutting Units

Page 7 -- 14 Rev. A

Groundsmaster 3505--D

| Categories | Lawn Mower Manual, Sprinkler and Irrigation Manuals, Toro Sprinkler and Irrigation Manuals |

|---|---|

| Tags | Toro Groundsmaster 3505 D |

| Download File |

|

| Document Type | Service Manual |

| Language | English |

| Product Brand | Toro. Customer Service Representatives are available by phone:

Monday - Friday 7:30 a.m. to 9:00 p.m. (CDT) - Saturday 8:00 a.m. to 8:00 p.m. (CDT) - Sunday 10:00 a.m. to 8:00 p.m. (CDT)

Canada 1-888-225-4886 USA 1-888-384-9939, Lawn Mower |

| Document File Type | |

| Publisher | toro.com |

| Wikipedia's Page | Toro Company |

| Copyright | Attribution Non-commercial |

(0 votes, average: 0 out of 5)