IMPORTANT: Do not hit wheel hub or puller with a

hammer during removal or installation. Hammering

may cause damage to the hydraulic wheel motor.

E. Insert both return springs into the holes of both

brake shoes. Make sure shoes fit snuggly against

the anchor pin and cam shaft.

5.

drum from the hydraulic motor shaft (see Special Tools

in this chapter). Remove woodruff key from the shaft.

Usewheelhubpullertoremovewheelhubandbrake

3. If the complete brake assembly was removed, se-

cure brake assembly to the brake bracket with four cap

screws and lock nuts. Tighten fasteners.

6.

brake lever. Separate adjustment rod from brake lever.

Remove cotter pin that retains adjustment rod to

4. Attach adjustment rod to the brake lever and secure

with cotter pin.

NOTE: The brake lever, backing plate, retainer clip, re-

turn springs, brake shoes and cam shaft can be re-

moved as a complete brake assembly.

5. Makesurethatwheelhubandhydraulic motorshafts

are thoroughly clean. Install key to the slot on the hy-

draulic motor shaft. Slide wheel hub and brake drum as-

sembly onto the shaft.

7.

If itis desired to remove the brake assembly from the

brakebracket,removefourcapscrewsandlocknutsse-

curing the assembly to the bracket.

6. Secure wheel hub and brake drum to the hydraulic

motor shaft with lock nut.

8.

Disassemble brake assembly as follows (Fig. 6):

NOTE: For proper brake operation, the brake shoes

and backing plate must be concentrically aligned with

the brake drum.

A. Removereturnspringsfromthebrakeshoes.Re-

move brake shoes from the backing plate.

7.

Then tighten four socket head screws and lock nuts that

secure the brake bracket and wheel motor to the frame.

To align brake shoes and drum, apply parking brake.

B. Matchmark brake cam and brake lever to assure

proper alignment during assembly. Remove retain-

ing clip from the brake cam. Pull brake lever from the

cam. Remove cam from backing plate.

8. Secure wheel to machine with four (4) lug nuts.

9.

as follows:

The brake bracket and wheel shield can be removed

9. Lower wheel to ground. Torque wheel lug nuts from

45 to 65 ft--lb (61 to 88 N--m) in a crossing pattern.

A. Remove lock nuts, spacers and socket head

screws securing the brake bracket, wheel shield and

hydraulic motor to the frame.

10.Torque lock nut (item 6) from 250 to 350 ft--lb (339 to

474 N--m). Release parking brake.

11.

Check brake adjustment and andadjust ifnecessary

B. Separate bracket and shield from the frame.

(see Adjust Brakes in the Adjustments section).

Installation (Fig. 5)

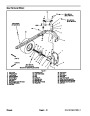

6

2

1.

If removed, insert four socket head screws through

the frame, hydraulic motor, spacers, wheel shield and

brake bracket. Secure with lock nuts, but do not fully

tighten.

5

1

2.

Assemble brake assembly as follows (Fig. 6):

A. If removed, secure backing plate to the brake

bracket with four cap screws and lock washers.

B. Apply antiseize lubricant to cam shaft splines. In-

sert cam shaft through the backing plate.

4

3

7

Figure 6

5.

6.

7.

1.

2.

3.

4.

Return spring

Retaining clip

Cam shaft

Anchor pin

C. Attach brake lever to the cam shaft. Make sure

matchmarks are aligned properly. Secure lever to

shaft with retainer clip.

Brake shoe (toe end)

Brake shoe (heel end)

Backing plate

D. Lubricate brake shoe pivot points with a light

coating of grease. Position both brake shoes on the

backing plate so that the concave heels attach to the

anchor pin.

Groundsmaster 3505--D

Page 6 -- 9

Chassis

| Categories | Lawn Mower Manual, Sprinkler and Irrigation Manuals, Toro Sprinkler and Irrigation Manuals |

|---|---|

| Tags | Toro Groundsmaster 3505 D |

| Download File |

|

| Document Type | Service Manual |

| Language | English |

| Product Brand | Toro. Customer Service Representatives are available by phone:

Monday - Friday 7:30 a.m. to 9:00 p.m. (CDT) - Saturday 8:00 a.m. to 8:00 p.m. (CDT) - Sunday 10:00 a.m. to 8:00 p.m. (CDT)

Canada 1-888-225-4886 USA 1-888-384-9939, Lawn Mower |

| Document File Type | |

| Publisher | toro.com |

| Wikipedia's Page | Toro Company |

| Copyright | Attribution Non-commercial |

(0 votes, average: 0 out of 5)