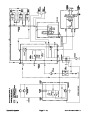

Traction Circuits

Forward

Atwosectiongearpumpisdirectlycoupledtothethehy-

drostat. Gear pump section (P2) supplies hydraulic flow

formaintaining100to150PSI(6.9to10.3bar)tothelow

pressure side of the traction circuit (charge), raising and

lowering the cutting units and operating the steering

system. The pump replenishes the closed loop traction

circuit with fluid from the hydraulic tank. The charge re-

lief valve in the hydrostat maintains sufficient pressure

so that pump flow is guided to the low pressure side of

the traction circuit through one of two check valves.

Pump flow in excess of replenishment requirements is

relieved through the charge relief valve back to gear

pump (P1) inlet.

The traction circuit of the hydraulic system consists of a

hydrostatconnectedinaclosedloopcircuittotwoorbital

rotor wheel motors.

The engine drives traction pump (P3) indirectly through

pulleysandaV--belt.Thetractionpumpisavariabledis-

placement piston pump. The traction pedal connects

through a cable to the trunnion shaft and swash plate of

the pump. With the engine running and the traction ped-

al in the neutral position, traction pump (P3) supplies no

flow to the wheel motors. When the traction pedal is

pressedtotheforward position,thecablefromthepedal

positions the swash plate in the traction pump so oil

flows out of the lower port. Oil flow out of the lower port

goes to the wheel motors and turns them in the forward

direction. Oil flowing out of the wheel motors returns to

the upper port of the hydrostat and is continuously

pumped out of the lower port.

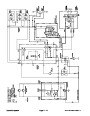

Reverse

The traction circuit operates essentially the same in re-

verse as it does in forward. However, there are a few dif-

ferences in operation.

When the reverse traction pedal is depressed, the cable

from the pedal positions the swash plate in the traction

pump (P3) so oil flows out of the upper port. Oil flow out

of the upper port goes to the wheel motors and turns

theminthereversedirection.Oilflowingoutofthewheel

motors returns to the lower port of the hydrostat and is

continuously pumped out of the upper port.

As the load increases, forward traction circuit pressure

can increase to the relief valve setting of 3000 PSI (207

bar). If pressure exceeds the relief setting, oil flows

through the relief valve in the hydrostat to the low pres-

sure side of the closed loop traction circuit.

Thetractionpumpusesasmallamountofhydraulicfluid

for internal lubrication. Fluid is designed to leak across

pump parts into the case drain. This leakage results in

the loss of hydraulic fluid from the closed loop traction

circuit that must be replenished.

Groundsmaster 3505--D

Page 4 -- 9

Hydraulic System

| Categories | Lawn Mower Manual, Sprinkler and Irrigation Manuals, Toro Sprinkler and Irrigation Manuals |

|---|---|

| Tags | Toro Groundsmaster 3505 D |

| Download File |

|

| Document Type | Service Manual |

| Language | English |

| Product Brand | Toro. Customer Service Representatives are available by phone:

Monday - Friday 7:30 a.m. to 9:00 p.m. (CDT) - Saturday 8:00 a.m. to 8:00 p.m. (CDT) - Sunday 10:00 a.m. to 8:00 p.m. (CDT)

Canada 1-888-225-4886 USA 1-888-384-9939, Lawn Mower |

| Document File Type | |

| Publisher | toro.com |

| Wikipedia's Page | Toro Company |

| Copyright | Attribution Non-commercial |

(0 votes, average: 0 out of 5)