Procedure for Logic (Counterbalance) Valve (LC1)

Pressure Test:

C. To increase pressure setting, turn the adjust-

mentshaftonthevalveinaclockwisedirection.A1/8

turn on the shaft will make a measurable change in

counterbalance pressure.

NOTE: If the counterbalance system is functioning, the

machine should normally settle slightly when theengine

is started.

D. To decrease pressure setting, turn the adjust-

ment shaft on the valve in a counterclockwise direc-

tion. A 1/8 turn on the shaft will make a measurable

change in counterbalance pressure.

1.

Make sure hydraulic oil is at normal operating tem-

perature.

2.

lowered and off. Make sure engine is off and the parking

brake is engaged.

Parkmachineonalevelsurfacewiththecuttingunits

E. Tightenlocknut.Checkcounterbalancepressure

(steps 6 and 7) and readjust as needed.

F. Replace hex cap to Logic valve (LC1).

Shut off engine.

3.

Read Precautions for Hydraulic Testing.

9.

WARNING

10.Relieve hydraulic system pressure (See Relieving

Hydraulic System Pressure in the General Information

section).Disconnecttestgaugewithhosefrommanifold

block. Install plug into hydraulic manifold port (G2) and

torque plug 120 in--lb (13.6 N--m).

Before disconnecting or performing any work

on the hydraulic system, all pressure in the

system must be relieved. See Relieving Hy-

draulic System Pressure in the General Infor-

mation section.

1

4.

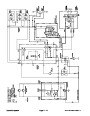

Remove plug from hydraulic manifold port (G2) (Fig.

25).

5.

attached to port (G2).

Install hydraulic pressure gauge with hydraulic hose

2

CAUTION

Figure 25

Keepawayfromdecksduringtesttopreventper-

sonal injury from the cutting blades.

1.

Hydraulic manifold

2.

Manifold port (G2)

3

6.

Start engine and move throttle to full speed (3050 +

50

RPM). Do not engage or raise the cutting units.

4

2

7.

250

The standard counterbalance pressure should be

PSI with a range of 180 to 300 psi.

8.

be performed as follows:

Ifnecessary,adjustmentoftheLogicvalve(LC1)can

1

NOTE: Do not remove the Logic valve from the hy-

draulic manifold for adjustment.

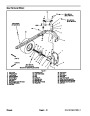

Figure 26

3.

4.

A. Remove hex cap from logic valve (Fig. 26).

B. Loosen lock nut.

1.

2.

Manifold assembly

Logic valve (LC1)

Hex cap

Lock nut

Groundsmaster 3505--D

Page 4 -- 39

Hydraulic System

| Categories | Lawn Mower Manual, Sprinkler and Irrigation Manuals, Toro Sprinkler and Irrigation Manuals |

|---|---|

| Tags | Toro Groundsmaster 3505 D |

| Download File |

|

| Document Type | Service Manual |

| Language | English |

| Product Brand | Toro. Customer Service Representatives are available by phone:

Monday - Friday 7:30 a.m. to 9:00 p.m. (CDT) - Saturday 8:00 a.m. to 8:00 p.m. (CDT) - Sunday 10:00 a.m. to 8:00 p.m. (CDT)

Canada 1-888-225-4886 USA 1-888-384-9939, Lawn Mower |

| Document File Type | |

| Publisher | toro.com |

| Wikipedia's Page | Toro Company |

| Copyright | Attribution Non-commercial |

(0 votes, average: 0 out of 5)