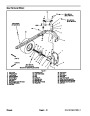

Disassembly (Fig. 7)

Park machine on a level surface, lower cutting units,

Assembly (Fig. 7)

1.

1. Position rear fork through the frame.

stop engine, engage parking brake and remove key

from the ignition switch.

2.

Install lock washer, thrust washer and cap screw to

the rear fork shaft. Torque cap screw from 60 to 80 ft--lb

(81 to 108 N--m). Make sure fork turns freely after cap

screw has been tightened.

2.

Remove hood from the machine (see Traction Unit

Operator’s Manual).

3.

wheel hub, place greased bearing cone into inner bear-

ing cup. Install new seal.

If seal and inner bearing were removed from the

WARNING

Beforejackingupthemachine,reviewandfollow

Jacking Instructions in Chapter 1 -- Safety.

4. Slidewheelhubontomachine.Positiongreasedout-

er bearing and tab washer onto shaft.

5.

bearings.Backoffjamnutandthen,whilerotatingwheel

hub, torque nut from 15 to 20 in--lb (1.7 to 2.3 N--m).

Install jam nut onto shaft and tighten fully to seat

3.

Chockfrontwheels.Jackuprearwheelenoughtoal-

low the removal of the rear fork. Support machine with

jack stands or blocking.

6.

Install nut retainer, cotter pin and dust cap.

4.

Remove lug nuts from rear wheel drive studs. Re-

move rear wheel assembly from machine.

7.

Secure hydraulic steering cylinder to the rear fork as

follows:

5.

Separate hydraulic steering cylinder from the rear

fork as follows:

A. Swing steering cylinder to the rear fork.

A. Remove both jam nuts securing the ball joint to

the rear fork.

B. Install ball joint to rear fork.

C. Secure ball joint to rear fork with two (2) jam nuts.

Tighten the first jam nut from 65 to 85 ft--lb (88 to 115

N--m), then tighten the second jam nut to the same

specification.

B. Separate ball joint from the rear fork.

C. Swing steering cylinder clear of the rear fork.

6.

Remove dust cap from hub. Remove cotter pin, nut

8.

(4)

Secure wheel assembly to the wheel hub with four

lug nuts.

retainer, jam nut and tab washer to allow removal of

wheel hub and bearings. Pull wheel hub with bearings

and seal from machine.

9.

Lower machine to the ground. Torque lug nuts in a

crossing pattern from 45 to 65 ft--lb (61 to 88 N--m).

7.

If necessary, remove seal and bearings from wheel

hub.

10.Lubricate

grease fittings (see Traction Unit Opera-

tor’s Manual).

8.

Inspect bearing cups in wheel hub for wear or dam-

age. If bearing cups are damaged, replace the wheel

hub.

CAUTION

Support rear fork to prevent its falling during re-

moval and installation. Personal injury or dam-

age to the fork may result from improper han-

dling.

9.

from the rear fork shaft. Slide rear fork from machine.

Remove cap screw, thrust washer and lock washer

10.Check

flange bushings in rear casting for wear or

damage. Replace bushings if necessary.

Groundsmaster 3505--D

Page 6 -- 11

Chassis

| Categories | Lawn Mower Manual, Sprinkler and Irrigation Manuals, Toro Sprinkler and Irrigation Manuals |

|---|---|

| Tags | Toro Groundsmaster 3505 D |

| Download File |

|

| Document Type | Service Manual |

| Language | English |

| Product Brand | Toro. Customer Service Representatives are available by phone:

Monday - Friday 7:30 a.m. to 9:00 p.m. (CDT) - Saturday 8:00 a.m. to 8:00 p.m. (CDT) - Sunday 10:00 a.m. to 8:00 p.m. (CDT)

Canada 1-888-225-4886 USA 1-888-384-9939, Lawn Mower |

| Document File Type | |

| Publisher | toro.com |

| Wikipedia's Page | Toro Company |

| Copyright | Attribution Non-commercial |

(0 votes, average: 0 out of 5)