2.

Remove plugs from piston pump openings that were

10.Using a straight edge across the lower face of the

pumppulley,verifytractionbeltalignmentacrossengine

and pump pulleys. Slide pulley and taper lock bushing

on pump shaft so that traction belt and straight edge are

aligned indicating correct position of pump pulley. Se-

cure taper lock bushing in position with set screw.

placed during disassembly. Install hydraulic fittings with

new o--rings to their original positions on the piston

pump.

NOTE: Ifinstallinganewgearpumptothepistonpump,

make sure to remove the plug from the suction port of

the gear pump (Fig. 53). The gear pump suction fitting

must be on the same side as the trunnion of the piston

pump.

IMPORTANT: Whentightening bushing capscrews,

tighten in three equal steps and inacircular pattern.

11.

Securetaperlockbushingbytighteningthree(3)cap

3.

Remove plugs that were placed during disassembly

screws to a torque from 90 to 120 in--lb (10.2 to 13.6

N--m) in three equal steps and in a circular pattern to se-

cure pulley and taper lock bushing.

from gear pump openings. Position o--ring(item 54) and

gearpumptothepistonpumpandsecurewithflatwash-

ers (item 55) and cap screws (item 56). Torque cap

screws from 27 to 31 ft--lb (37 to 42 N--m).

12.Check

that belt alignment is still correct. If needed,

loosenandre--adjustpulleyandtaperlockbushingloca-

tion on pump shaft to allow for correct belt alignment.

4.

Place key into pump shaftslot. Slidetaper lockbush-

ing onto the piston pump shaft with bushing flange to-

ward pump housing.

13.Remove

from hydraulic hoses. Connect all hydraulic hoses with

new o--rings to piston and gear pumps.

plugs that were placed during disassembly

5.

Make sure that tapered surfaces of pulley and taper

lock bushing are thoroughly clean (no oil, grease, dirt,

rust, etc.).

14.Install

Neutral Arm Assembly Installation in this section).

neutral arm assembly to the piston pump (see

6.

Position pulley to taper lock bushing and align non--

15.Fill

tion Unit Operator’s Manual).

hydraulic tank with new hydraulic fluid (see Trac-

threaded holes of pulley with threaded holes ofbushing.

Loosely install three (3) cap screws with lock washers to

bushing and pulley.

16.Adjust

traction drive for neutral (see Traction Unit

Operator’s Manual).

CAUTION

Support piston and gear pumps when installing

them to the machine to prevent them from falling

and causing personal injury.

7.

Position pump mount plate with pumps, pump pulley

and idler assembly to the machine. Install fasteners and

spacers securing the pump mount plate to the engine

and pump support (Fig. 52). Tighten fasteners securely.

8.

mount plate, piston pump and engine mount with re-

moved fasteners and spacers.

Position and secure pump support (item 28) to pump

2

1

9.

Install traction belt (see Traction Unit Operator’s

Manual).

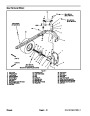

Figure 53

1.

Gear pump

2.

Suction port

Hydraulic System

Page 4 -- 82

Groundsmaster 3505--D

| Categories | Lawn Mower Manual, Sprinkler and Irrigation Manuals, Toro Sprinkler and Irrigation Manuals |

|---|---|

| Tags | Toro Groundsmaster 3505 D |

| Download File |

|

| Document Type | Service Manual |

| Language | English |

| Product Brand | Toro. Customer Service Representatives are available by phone:

Monday - Friday 7:30 a.m. to 9:00 p.m. (CDT) - Saturday 8:00 a.m. to 8:00 p.m. (CDT) - Sunday 10:00 a.m. to 8:00 p.m. (CDT)

Canada 1-888-225-4886 USA 1-888-384-9939, Lawn Mower |

| Document File Type | |

| Publisher | toro.com |

| Wikipedia's Page | Toro Company |

| Copyright | Attribution Non-commercial |

(0 votes, average: 0 out of 5)