5.

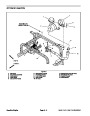

curing the hydraulic motor to the fork.

Remove both socket head screws and lock nuts se-

Installation (Fig. 2)

If wheel motor or hub was removed, install hub and

1.

IMPORTANT: Support wheel and wheel motor when

jacking up the front of the machine to prevent hy-

draulic tube damage.

motor (see Front Wheel Motor Installation in the Service

and Repairs section of Chapter 4 – Hydraulic System).

2.

3.

spindle and drive studs through wheel. Make sure valve

stem and hydraulic motor are on opposite sides of the

wheel.

Position hydraulic motor and hub to the front fork.

Install spindle to drive studs and wheel hub. Insert

WARNING

Before jacking up the machine, review and follow

Jacking Instructions in Chapter 1 – Safety.

4.

For Sand Pro 5040 and Infield Pro 5040 machines,

secure front wheel as follows:

6.

Jack up front of machine slowly until the hydraulic

motor and flangettes can be removed from the fork. Re-

move flangettes, spindle, wheel and motor from the fork.

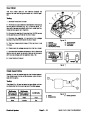

A. Install four (4) lug nuts onto drive studs.

B. Torque lug nuts evenly in a crossing pattern from

7.

Slide flangettes and bearing assembly from the

spindle. Separate flangettes from the bearing.

45

to 55 ft–lb (61 to 75 N–m).

5.

secure front wheel as follows:

For Sand Pro 3040 and Infield Pro 3040 machines,

8.

remove front wheel as follows:

For Sand Pro 5040 and Infield Pro 5040 machines,

A. If studs were removed from wheel weight adapt-

ers, thread studs fully into the correct end of the

adapter (Fig. 3).

A. Remove four (4) lug nuts from the drive studs.

B. Remove wheel from the drive studs and spindle.

B. Install two (2) lug nuts and two (2) wheel weight

adapters with studs onto drive studs.

9.

remove front wheel as follows:

For Sand Pro 3040 and Infield Pro 3040 machines,

C. Torque lug nuts and wheel weight adapters even-

ly in a crossing pattern from 45 to 55 ft–lb (61 to 75

N–m).

CAUTION

To prevent personal injury, make sure that

wheel weight is supported as it is removed

from the machine. Wheel weight weighs

approximately 25 pounds (11.4 kg).

CAUTION

To prevent personal injury, make sure that

wheel weight is supported as it is installed to

the machine. Wheel weight weighs approxi-

mately 25 pounds (11.4 kg).

A. Remove two (2) lock nuts and thrust washers that

secure wheel weight to wheel.

B. Carefully slide wheel weight from weight studs.

D. Carefully slide wheel weight onto weight studs.

C. Loosen and remove two (2) lug nuts and two (2)

wheel weight adapters with studs.

E. Secure wheel weight to wheel with two (2) thrust

washers and lock nuts.

D. Pull wheel from machine.

6

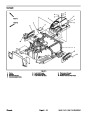

0o

30o + 5o

10.Separate

spindle from drive studs and wheel hub.

11.

Secure hydraulic motor and hub to the machine to

prevent damaging the hydraulic lines.

12.If

wheel motor or hub removal is necessary, see

Front Wheel Motor Removal in the Service and Repairs

section of Chapter 4 – Hydraulic System.

WHEEL STUD

WEIGHT STUD

(.500–13 UNC–2B)

(.500–20

UNF–2B)

Figure 3

Sand Pro & Infield Pro 3040/5040

Page 6 – 5

Chassis

| Categories | Lawn Mower Manual, Sprinkler and Irrigation Manuals, Toro Sprinkler and Irrigation Manuals |

|---|---|

| Tags | Toro 3040, Toro 5040 |

| Download File |

|

| Document Type | Service Manual |

| Language | English |

| Product Brand | Toro. Customer Service Representatives are available by phone:

Monday - Friday 7:30 a.m. to 9:00 p.m. (CDT) - Saturday 8:00 a.m. to 8:00 p.m. (CDT) - Sunday 10:00 a.m. to 8:00 p.m. (CDT)

Canada 1-888-225-4886 USA 1-888-384-9939, Lawn Mower |

| Document File Type | |

| Publisher | toro.com |

| Wikipedia's Page | Toro Company |

| Copyright | Attribution Non-commercial |

(0 votes, average: 0 out of 5)