Procedure for Traction Relief Valve (R3) Pressure

Test:

11.Pressure gauge reading should be at least 3200 PSI

(220.7 bar) higher than charge pressure. Record test

results.

1.

Make sure hydraulic oil is at normal operating tem-

perature by operating the machine for approximately 10

minutes.

Example: Consider a machine that has a charge pres-

sure of 240 PSI (16.6 bar). The traction relief pressure

for this machine should be at least 3440 PSI (237.3 bar).

2.

Park machine on a level surface with the attachment

removed. Make sure engine is off and that the parking

brake is applied.

12.Release traction pedal and turn engine off.

NOTE: If the relief pressure cannot be obtained and en-

gine speed drops excessively (below 2800 RPM) as the

traction pedal is depressed, engine performance should

be evaluated (see Chapter 3 – Gasoline Engine).

3.

4.

Read and follow Precautions for Hydraulic Testing.

Make sure that traction pedal is adjusted to the neu-

tral position (see Operator’s Manual).

13.If

traction relief pressure is incorrect, inspect traction

IMPORTANT: Make sure to thoroughly clean around

all hydraulic connections that will be disassembled.

relief valve (R3) in hydrostat (see the Sauer–Danfoss

(Sundstrand) 15 Series Service Manual at the end of this

chapter). Clean or replace relief valve as needed. If re-

lief valve is in good condition, acceleration valves and

charge check valve in hydrostat should be inspected as

well. A worn or damaged hydrostat could be considered

if relief, check and acceleration valves are in good condi-

tion.

5.

forming the Charge Relief Valve (R2) Pressure Test.

Determine the hydrostat charge pressure by per-

6.

hydrostat (Fig. 20). Install pressure gauge to test port.

Remove plug from forward traction port on bottom of

7.

at low idle speed. Check for hydraulic leakage and cor-

rect before proceeding with test.

After installing pressure gauge, start engine and run

14.If

traction relief pressure is correct and a traction cir-

cuit problem exists, check traction pump (P1) flow (see

Traction Pump (P1) Flow Test in this section) and wheel

motor efficiency (see Wheel Motor Efficiency Test in this

section).

8.

Operate engine at full speed (3400 RPM).

15.When

sure gauge from machine and install plug into hydrostat

port.

testing is complete, remove hydraulic pres-

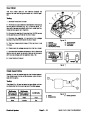

CAUTION

Use extreme caution when taking gauge read-

ings. The front wheel will be turning.

16.Make

Manual).

sure hydraulic tank is full (see Operator’s

9.

Sit in the operator seat, make sure that the parking

brake is applied and slowly push traction pedal in the

forward direction. Depress traction pedal to between

1

1/3

and 1/2 of pedal travel. Engine speed should de-

crease to approximately 2800 RPM as pedal is de-

pressed.

2

IMPORTANT: DO NOT hold system at relief for more

than a few seconds.

3

IMPORTANT: DO NOT allow pressure to exceed

4000

PSI (275.8 bar) during testing.

10.While

gauge and record pressure when the traction circuit re-

lief valve opens.

depressing traction pedal, watch the pressure

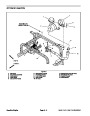

Figure 20

1.

2.

Hydrostat (from below)

Forward traction port

3.

Traction rod

Sand Pro & Infield Pro 3040/5040

Page 4 – 25

Hydraulic System

| Categories | Lawn Mower Manual, Sprinkler and Irrigation Manuals, Toro Sprinkler and Irrigation Manuals |

|---|---|

| Tags | Toro 3040, Toro 5040 |

| Download File |

|

| Document Type | Service Manual |

| Language | English |

| Product Brand | Toro. Customer Service Representatives are available by phone:

Monday - Friday 7:30 a.m. to 9:00 p.m. (CDT) - Saturday 8:00 a.m. to 8:00 p.m. (CDT) - Sunday 10:00 a.m. to 8:00 p.m. (CDT)

Canada 1-888-225-4886 USA 1-888-384-9939, Lawn Mower |

| Document File Type | |

| Publisher | toro.com |

| Wikipedia's Page | Toro Company |

| Copyright | Attribution Non-commercial |

(0 votes, average: 0 out of 5)